ETICS Fixings

Fixings and accessories for the installation of ETICS insulation panels

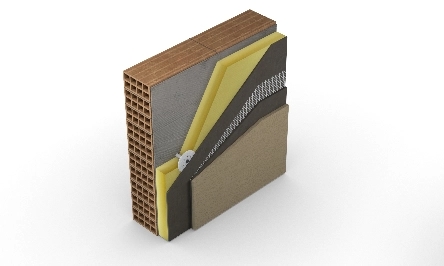

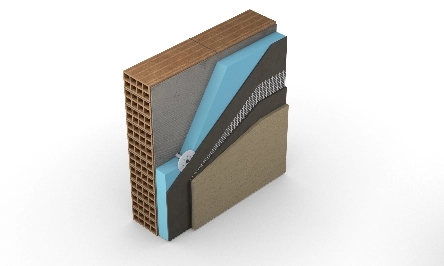

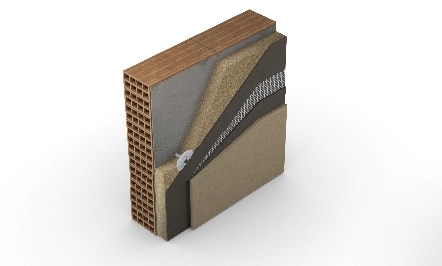

What is the ETICS system?

Thermal insulation, known as ETICS (External Insulation Composite System), is a comprehensive method which allows the insulation of both newly constructed buildings and those undergoing renovation.

The covering is adapted to the geometry of the building, including those which are most complex, resolving the majority of thermal bridges of the building.

Its installation ensures a drastic reduction of energy dissipated to the exterior, reducing the need for heating and cooling, allowing continuous energy savings throughout the year (25% of the heat of a home is lost through walls, windows and doors) and maintaining a stable temperature. The reduction of pollutant gas emissions protects the environment.

At a time when energy efficiency and sustainability policies are becoming increasingly important, it is essential to have a system such as ETICS which reduces the need for heating and cooling, which also entails a reduction of pollutant gas emissions, mainly CO2, contributing to protecting the environment.

Advantages of ETICS

- Reduction of energy consumption of the home = Economic savings.

- Environmentally friendly. Reduction of CO2 emissions.

- Elimination or minimisation of thermal bridges of the building.

- Improved thermal comfort of the home.

- Increases the value of the home.

- Reduction of noise. Better acoustics.

- Reduced risk of condensation, mould and mildew.

- Easy installation. Does not generate loss of area of the home.

- Protects the structure of the building.

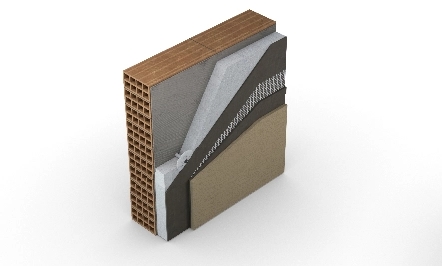

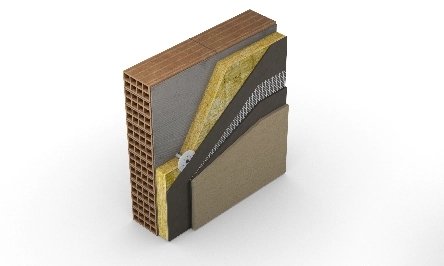

Types of insulation plates

Expanded polystyrene (EPS)

Its composition of plastic material avoids deterioration and the appearance of mould while offering impermeability for the facade of the home. It is a light material which is easy to install and handle, which adapts to the support with a regular and aesthetic finish. Offers great thermal insulation.

Mineral wool (MW)

Improves acoustics in the enclosure and offers stability of the panel in a high temperature environment (>1,000 ºC) in addition to being a light material. This solution is very advantageous for the renovation of buildings located in areas with noise pollution. Due to its general nature, it must be completely protected from water.

Shaped polyurethane (PUR)

Rigid and lightweight, it offers maximum resistance, both thermal and mechanical: it is highly resistant to compression, friction and abrasion. Its lightness and high density offer greater dimensional stability and a variety of finishes.

Extruded polystyrene (XPS)

This is a thermal material formed by rigid sheets of foam with a closed cell structure, characterised by its high mechanical performance, its high durability, and being water resistant, thereby avoiding decomposition. Additionally, it incorporates flame retardant properties which protect it from fire. Available in various colours, its use is widespread for inverted roofs.

Expanded cork

Its 100% natural composition makes this material a light, manageable, waterproof material which is easy to cut. It offers excellent thermal and vibratory insulation. Flame retardant and elastic.

Depending on the construction characteristics, different types of insulations may be selected for the type of wall or space.

Sheets of insulation must be correctly attached to the base material using adhesive or mechanical fixings and following the recommendations of the technical datasheets. The joins between sheets must be perfectly fitted, monitoring planimetry during installation.

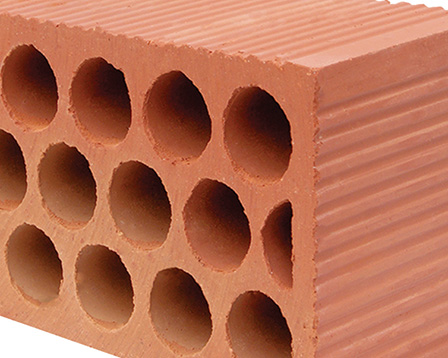

Types of base material

It is important to ascertain the characteristics of the material where the anchor is installed. In EAD 330196-01-0604, the base materials are established as categories of use, to simplify the evaluation of the performance of the anchor. Within these categories are groups of materials A, B, C, D and E.

Concrete

Solid partition

Hollow or perforated partition

Lightweight concrete with open structure

Ventilated concrete

Types of fixings for External Thermal Insulation Composite Systems (ETICS)

A good fixing allows perfect attachment of the insulation material for the parameters of the building, while restricting movements of expansion, contraction, warping, traction and/or compression of the insulation.

There are various possibilities when attaching insulation panels: mechanical fixings, polyurethane adhesives or with a combination of both. Additionally, there are spiral type accessories for attaching light and medium load accessories to the insulation panels, as well as accessories for mechanical anchors (rosettes or washers).

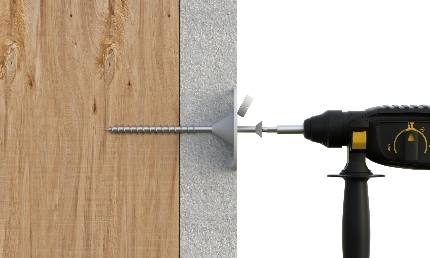

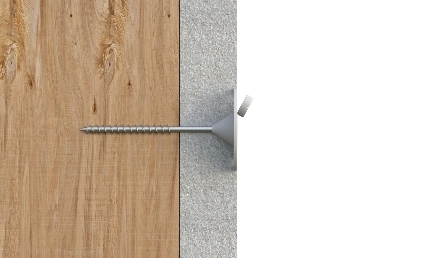

Mechanical fixings for insulation plates

Certified* fixings designed for secure attachment of ETICS panels, guaranteeing secure attachment to any base material.

Fixings for ETICS must be capable of resisting the suction of the wind which may affect the system, as well as eliminating the possibility of pulling off the insulation through the washer or head of the plastic anchor. In certain materials, it may be appropriate to use a washer of a larger diameter to increase resistance against the insulation being pulled off.

Accessories for fixings of insulation plates

Products which complement the range of mechanical fixings. Suitable for cases in which it is necessary to increase the diameter of the surface pressure of the fixing on the insulation panel to be installed. To do so, supplementary washers with a larger diameter are used.

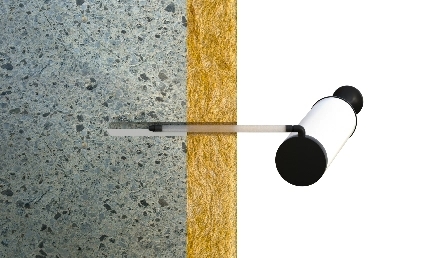

PU-EP polyurethane adhesive

Suitable for the quick and easy installation of ETICS plates, insulation panels and laminated plasterboard, as well as for application on multiple base materials.

Its high-density formulation ensures instant initial bonding and high adhesion strength, as well as rapid curing and low expansion, which entails savings of material, waiting times and application of other attachment methods such as screws or nails.

The attachment can be strengthened with mechanical

fixings**.

More information

Anchors for fixings on ETICS plates

Fixings for the installation of light accessories directly on external insulation panels.

Suitable for the installation of drains, electrical fixings, hoods, alarms, mailboxes, wall lamps, etc.

All components of the ETICS system must comply with the legal requirements of the ETA (European Technical Assessment) previously known as DITE in Spain, defined in EAD 330196-01-0604 “Plastic anchors made of virgin or non-virgin material for fixing of external thermal insulation composite systems with rendering”

**The mechanical anchors guarantee the strength of adhesion between the base material and the insulation, in case of the adhesive losing its bearing capacity, for example due to the hygrothermal effect which may cause thermal fluctuations and moisture to which the system may be subjected during the lifespan of the building.

Types of fixings for External Thermal Insulation Composite Systems (ETICS)

AIS-S

AIS

AIS-M

AIS-R

AIS-W

AIS-AM

PU-EP

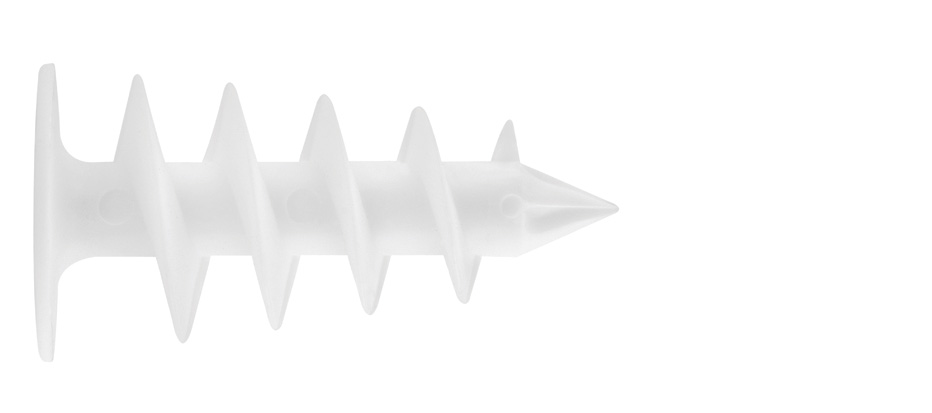

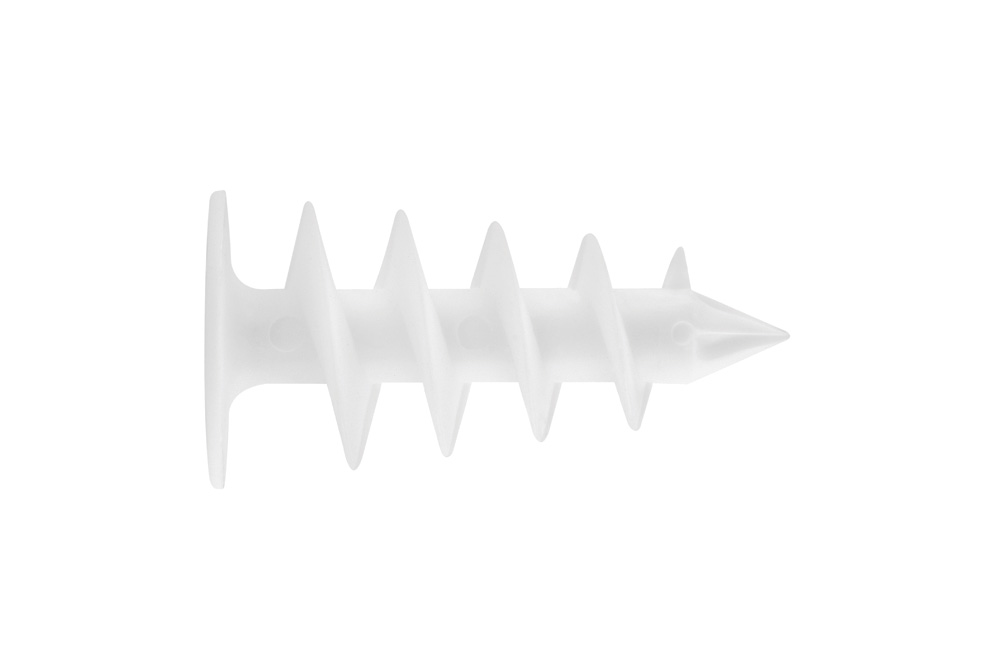

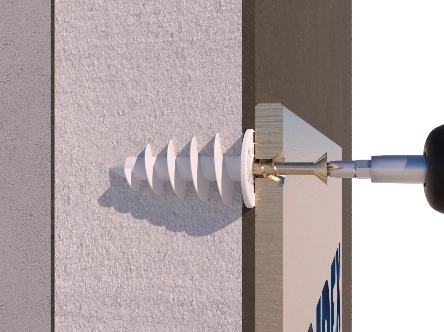

TE

TE

Anchor for attaching light loads on base materials such as expanded polystyrene (EPS), mineral wool (MW), shaped polyurethane (PUR) and extruded polystyrene (XPS).

Technical data

- Lengths: Ø 25 x 50 mm and Ø 25 x 90 mm.

- PA material.

- Installation outline T40.

- Compatible with Ø 4.5 and Ø 5 mm. screws.

Caractéristiques

- Its spiral structure is designed for adaptation to the insulation material.

- Prior drilling is not necessary.

- Quick and easy installation.

- Quick and easy installation.

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

PU-EP

POLYURETHANE ADHESIVE FOR ETICS/PANELS. Product certified in accordance with ETAG 004.

Installation options

More information

Installation options

More information

Adhesive suitable for the installation of ETICS (External Thermal Insulation Composite System) panels, insulating panels, and laminated plasterboard. Its high-density formulation ensures instant initial bonding and high adhesion strength.

Technical data

- Volume: 60-80 linear metres (750 ml).

- Specific density of the adhesive: 16-18 kg/m3.

- Thermal conductivity: 0.036 W/(m K) a 20 °C.

- Elongation at break: 20 - 30 (%).

- Flammability rating: E (B2).

- APPLICATION: GUN.

Caractéristiques

- Excellent adhesion to: concrete, brick, porotherm, drywall, aerated concrete and hollow concrete blocks, Styrofoam, Styrodur, mineral wool OSB’s, wood, etc.

- Enables quick progress of work.

- Easy application.

- Fast curing and low expansion.

- Resistant to humidity and low temperatures.

- Decreased consumption, cheaper implementation of works.

- Savings in terms of transport and storage.

- A layer of polyurethane adhesive under an insulation plate provides additional thermal insulation.

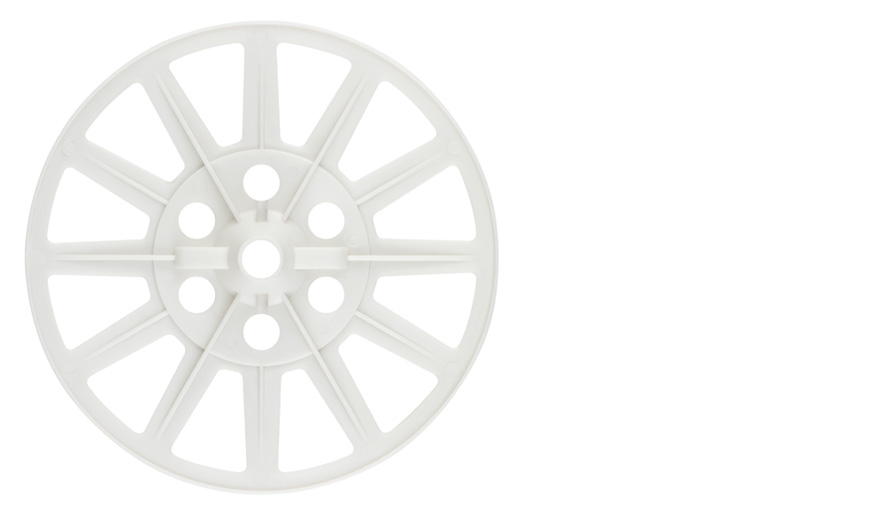

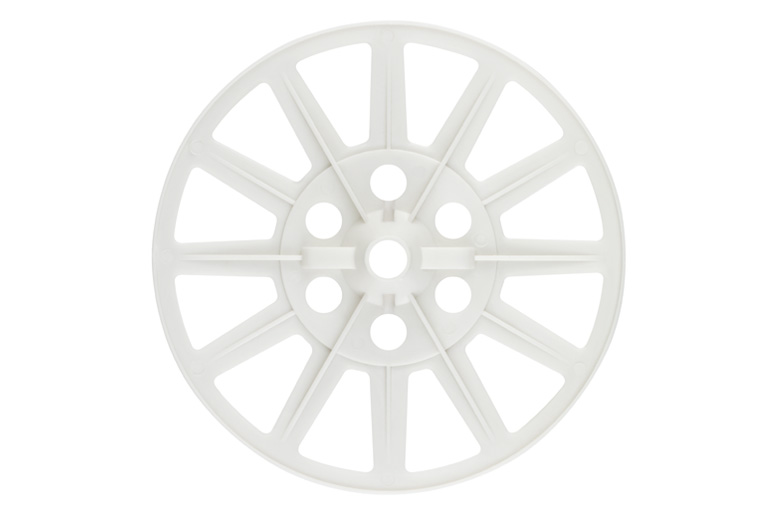

AIS-AM

Distribution washer for attachment of semi-rigid elements.

Technical data

- Diameter of washer: 85 mm.

Caractéristiques

- Improved distribution of loads on semi-rigid materials by increasing the contact area.

- For application with the or AIS-M plug.

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

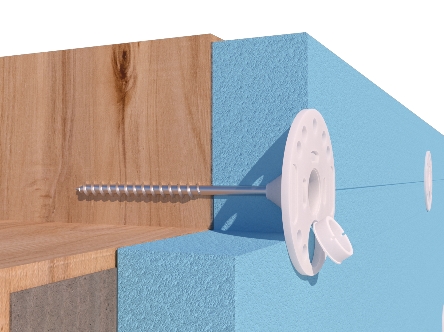

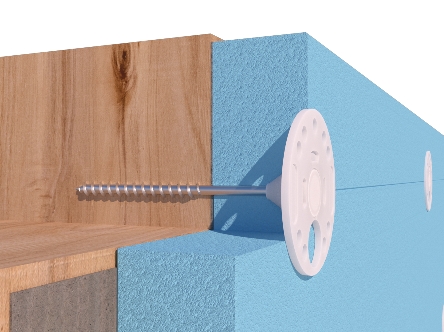

AIS-W

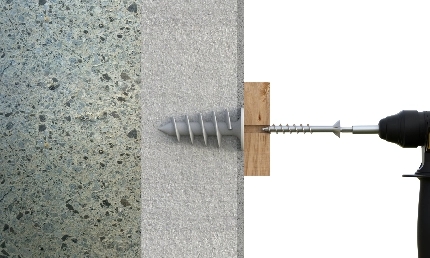

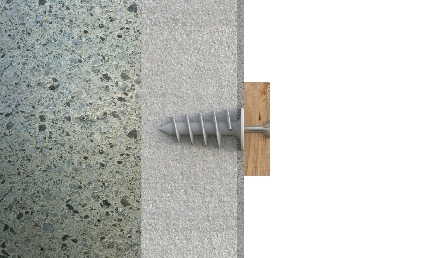

Pressure rosette with upper cap for attaching thermal insulation to a wooden or metal base by screw fixing.

Technical data

- Diameter of rosette: 60 mm.

- PP material.

- Compatible with Ø 4.5 and Ø 6 screws.

Caractéristiques

- The cap prevents thermal bridging.

- Quick and easy installation.

- For use with a wide range of screws.

- Allows the installation of insulation materials of different thicknesses.

- Compatible with AIS-R.

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

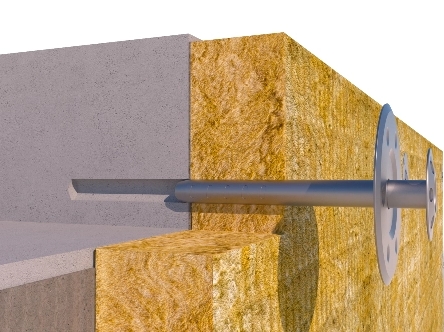

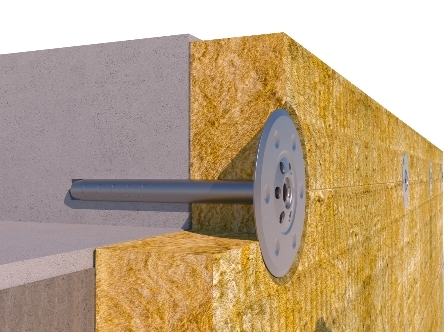

AIS-R

Distribution washer for attachment of semi-rigid elements.

Technical data

- Diameter of washer: 140 mm.

Caractéristiques

- Improved distribution of loads on semi-rigid materials by increasing the contact area.

- For application with the AIS-C or AIS-S plug.

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

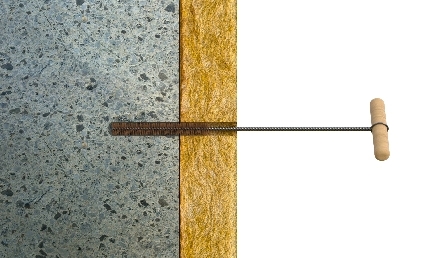

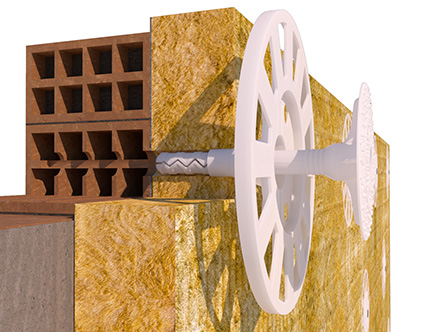

AIS-M

Punched metal fixing for attaching rigid insulation of expanded polystyrene (EPS), mineral wool (MW), shaped polyurethane (PUR), extruded polystyrene (XPS) and expanded cork on A and B type base materials.

Technical data

- Diameter of anchor: 8 mm.

- Diameter of washer: 35 mm.

- Effective depth: hef 40 mm.

- Lengths: from 90 mm to 300 mm.

Caractéristiques

- Fire resistant.

- Punched fixing.

- Quick and easy installation.

- Compatible with AIS-AM washer.

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

AIS

The INDEX AIS plug is a plug specially designed for attaching insulation panels of expanded polystyrene (EPS), mineral wool (MW), shaped polyurethane (PUR), extruded polystyrene (XPS) and expanded cork to A and B type base materials with or without plaster, mechanically to a surface or base material (wall or facade).

Technical data

- Diameter of anchor: 8 mm.

- Diameter of washer: 32 mm.

- Effective depth: hef 30 mm.

- White PP plug.

- Lengths: from 80 mm to 140 mm.

Caractéristiques

- Punched fixing plug.

- Quick installation.

- Without need for nail.

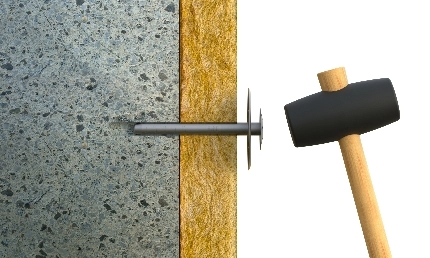

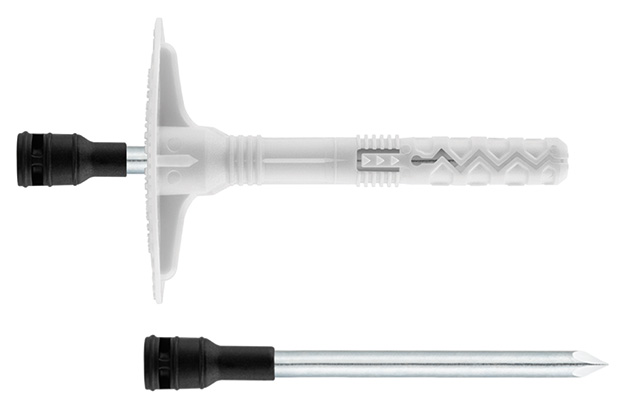

AIS-S

Plug with metal nail and polyamide cap for mechanical fixing of insulation panels.ETA approved.

Installation options

More information

Installation options

More information

The INDEX AIS-S plug is a plug specially designed for attaching insulation panels of expanded polystyrene (EPS), mineral wool (MW), shaped polyurethane (PUR), extruded polystyrene (XPS) and expanded cork to A, B, C, D and E type base materials with or without plaster, mechanically to a surface or base material (wall or facade).

It has European approval ETA 21-0823 for fixing of external thermal insulation composite systems.

Technical data

- Diameter of anchor: 10 mm.

- Diameter of washer: 60 mm.

- Effective depth: hef 50 mm.

- White PP plug and metal nail with black PA cap.

- Lengths: from 70 mm to 260 mm.

Caractéristiques

- Body in white and metal nail with black cover to facilitate monitoring on site and ensure the correct installation of the anchor.

- The metal nail guarantees high resistance to impacts.

- Geometry of the head specially designed to improve attachment of the plaster and other elements to be installed on the anchor.

- Reinforcements on the interior side of the head to improve its rigidity and avoid it breaking.

- Double expansion zone.

- Expansion zone 50 mm long.

- Indicator of depth of the anchor.

- Reduction of thermal bridge thanks to the PA cap.

- Marking of diameter and length on the body of the anchor.

- Compatible with distribution washer AIS-R.

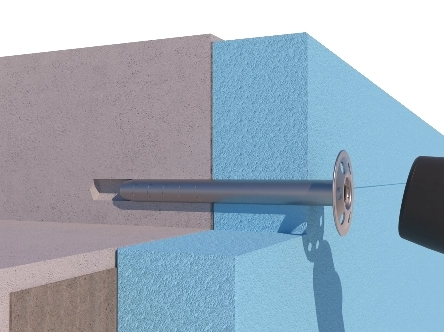

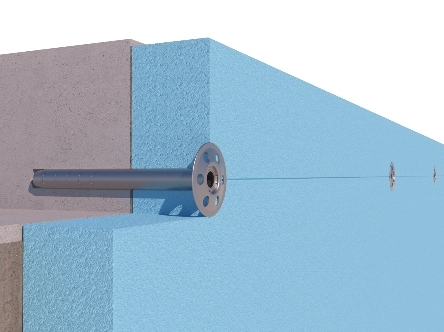

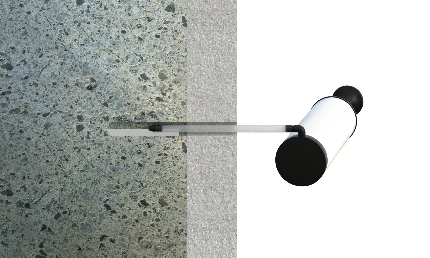

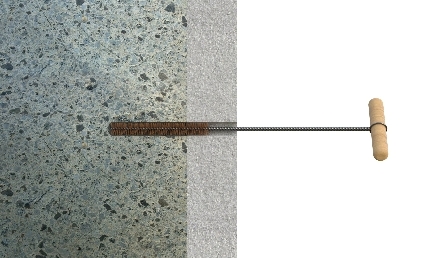

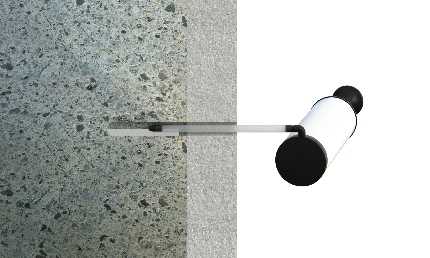

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

AIS-C

Polyamide plug with nail for mechanical fixing of insulation panels. ETA approved.

Installation options

More information

Installation options

More information

The INDEX AIS-C plug is a plug specially designed for attaching insulation panels of expanded polystyrene (EPS), mineral wool (MW), shaped polyurethane (PUR), extruded polystyrene (XPS) and expanded cork to A, B, C and D type base materials with or without plaster, mechanically to a surface or base material (wall or facade).

They have European approval ETA 21-0823 for fixing of external thermal insulation composite systems.

Technical data

- Diameter of anchor: 10 mm.

- Diameter of washer: 60 mm.

- Effective depth: hef 50 mm.

- White PP plug and black PA nail.

- Lengths: from 70 mm to 260 mm..

Caractéristiques

- Body in white and black nail to facilitate monitoring on site and ensure the correct installation of the anchor.

- Geometry of the head specially designed to improve attachment of the plaster and other elements to be installed on the anchor.

- Reinforcements on the interior side of the head to improve its rigidity and avoid it breaking.

- Double expansion zone.

- Expansion zone 50 mm long.

- Indicator of depth of the anchor.

- Reduction of thermal bridge thanks to its composition.

- Marking of diameter and length on the body of the anchor.

- Compatible with distribution washer AIS-R.

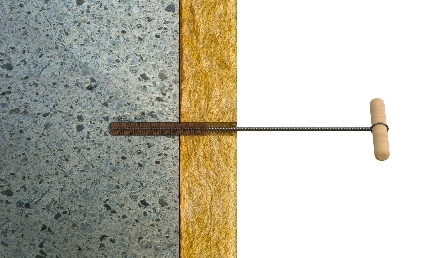

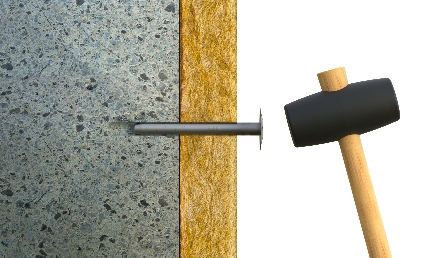

Installation process

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

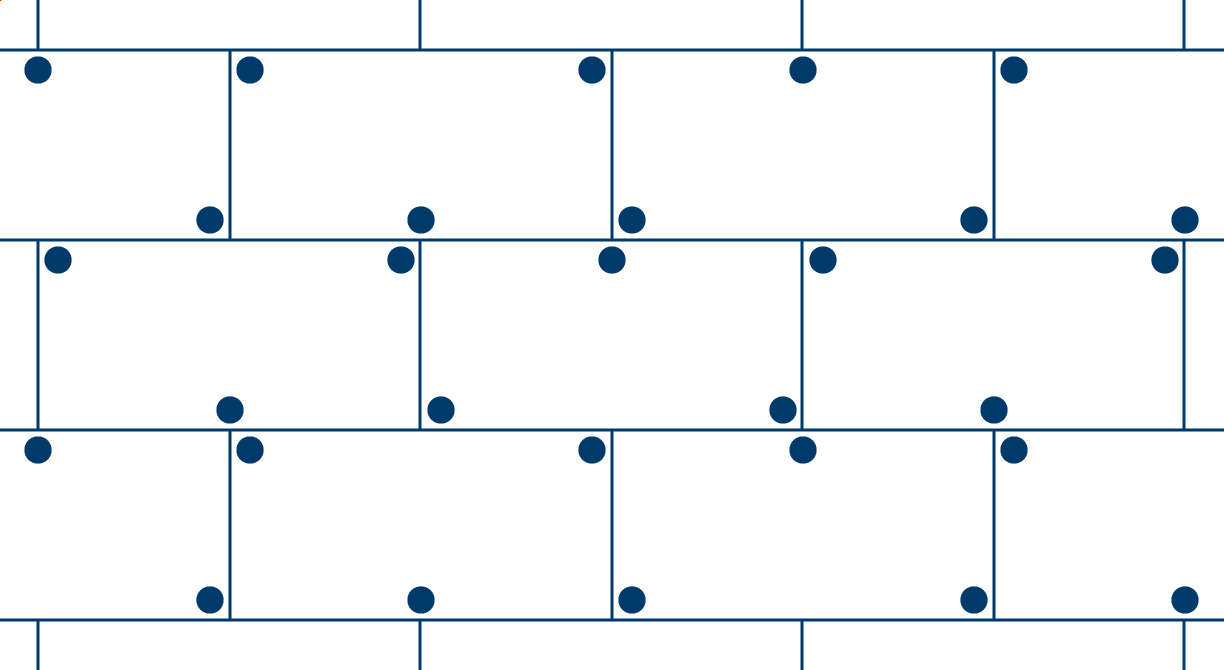

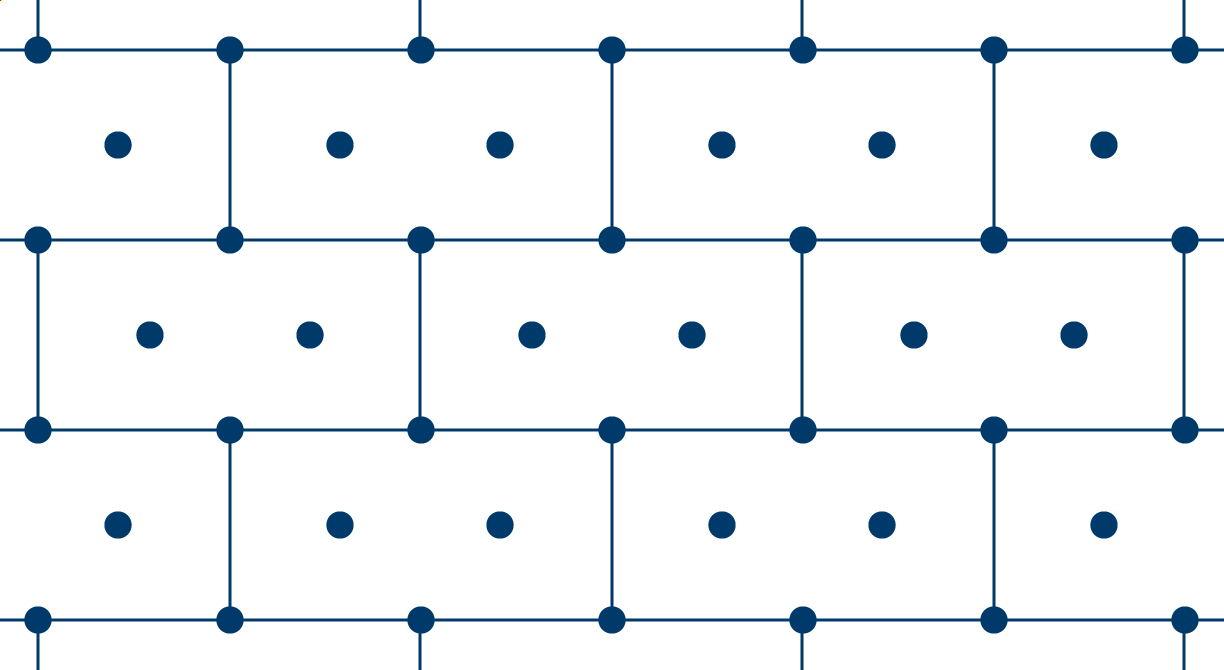

Fixing installation options for ETICS plates

The number of anchors and their layout will depend on various factors, which will allow the stability and safety of the facade to be guaranteed. To do so, it will be carried out in accordance with Eurocode 2 and in accordance with the regulations of each country. These factors are:

Characteristics and dimensions of the insulation

- Depending on the insulation material, its own weight will be generated, which will depend on the type of insulation used. The dimensions of the insulation will generate suction loads which must be ascertained to correctly scale the system.

- In certain cases, when we attach soft materials, it is recommended to use the selected anchor with a wide washer, such as the AIS-R, to increase the contact surface, avoiding deformation of the material to be attached and improving the distribution of loads over a greater contact area.

Height, location and position of the building

- For the scaling and layout of the number of anchors, the effects of wind, as well as the altitude, location and placement where the anchors will be installed must be taken into account, to guarantee the quality and total safety of our installation.

- In case of buildings where the properties of the base material are unknown, or where it may have been changed over time, tests must be carried out on site to determine the resistance values of the material.

Hygrothermal effects

- Temperature and moisture variations between the interior and exterior will generate significant variations which may affect the adhesive used to attach the insulation. To avoid this, it is recommended to use mechanical fixings which strengthen and resist these forces.

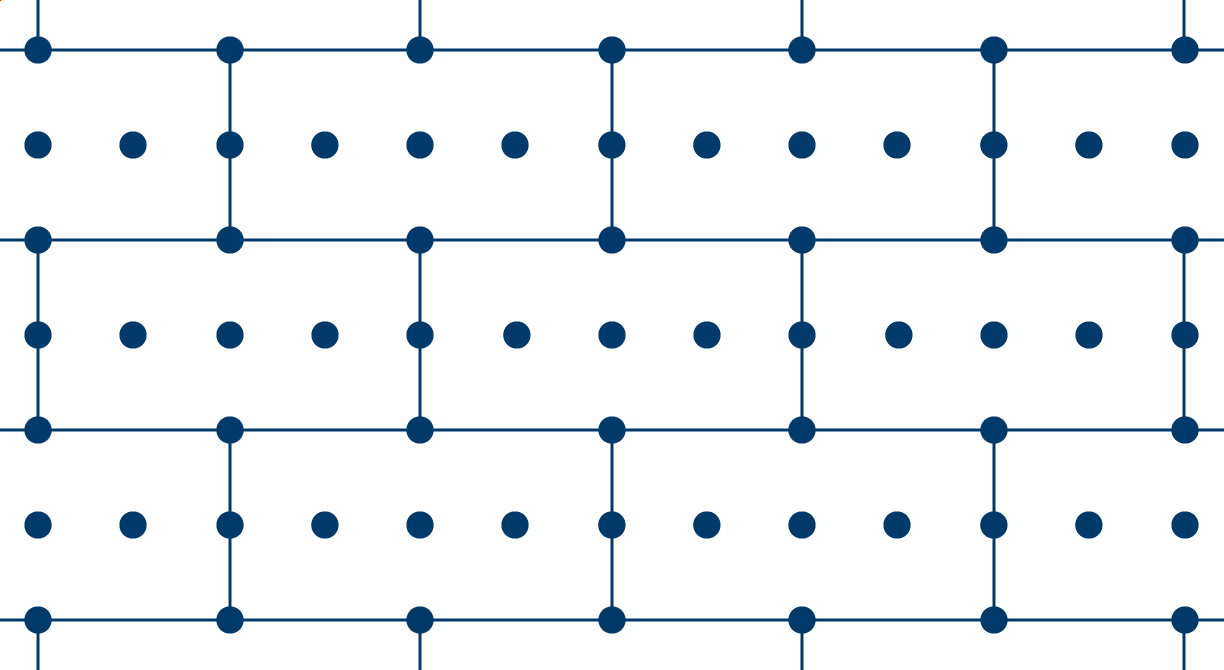

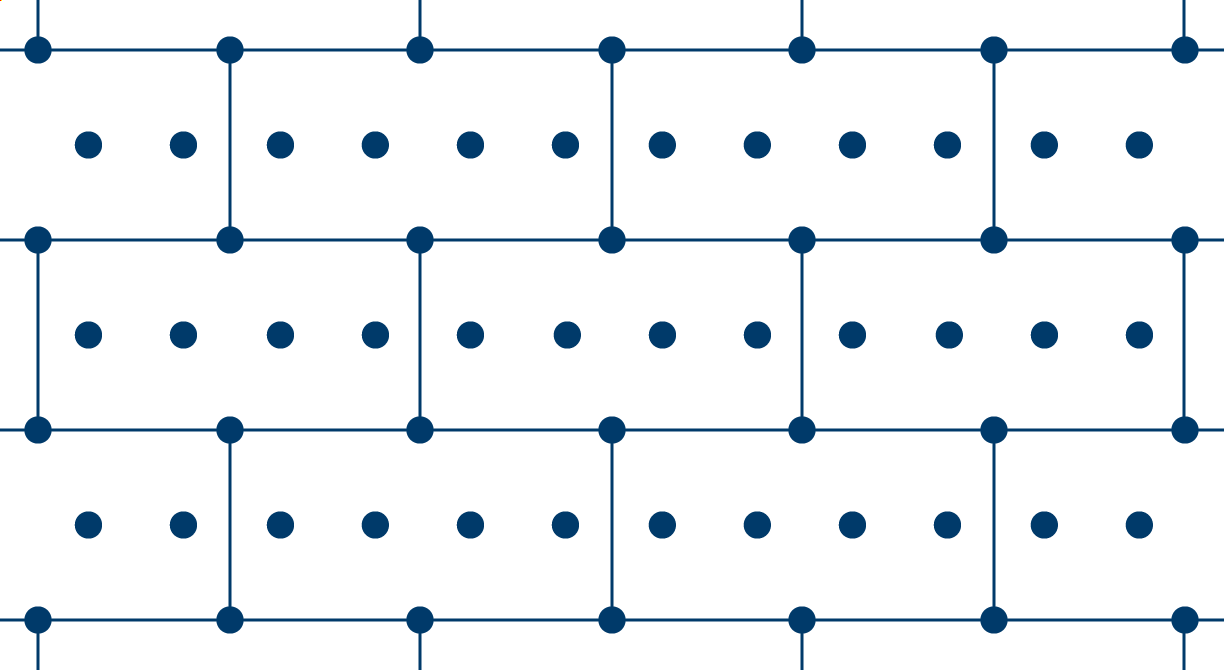

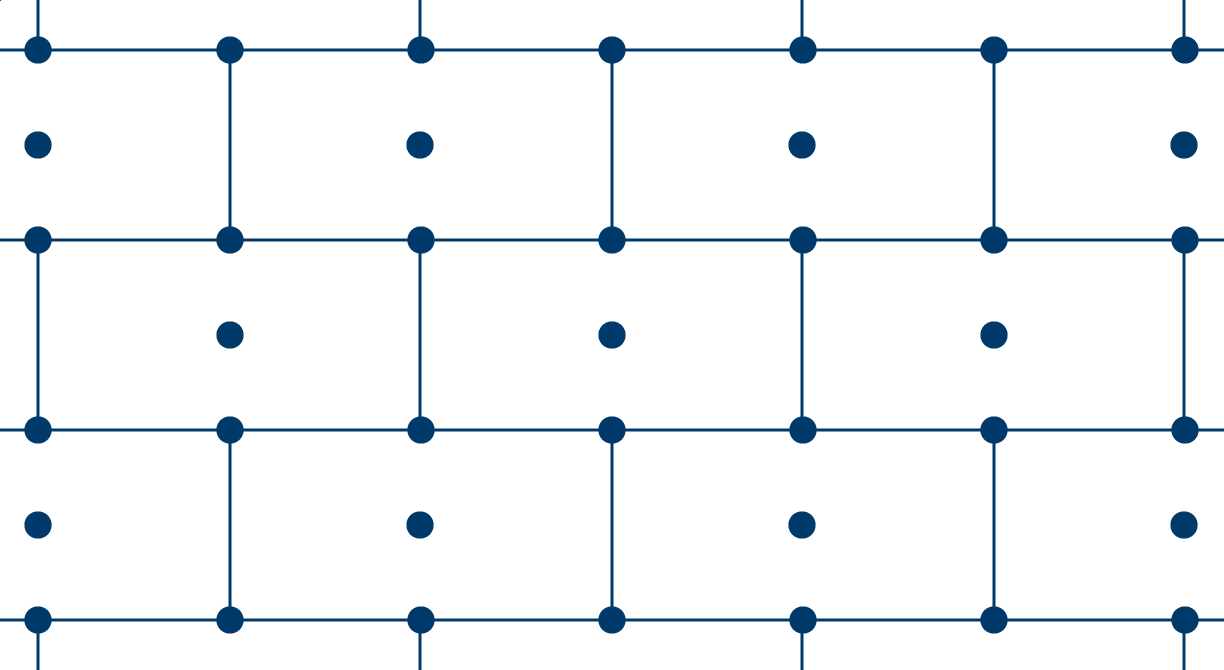

Depending on the number of anchors recommended, different layouts may be selected, considering an insulation panel of 1,000 x 500 mm.

- 6 pcs/m2 (A)

- 6 pcs/m2 (B)

- 8 pcs/m2

- 12 pcs/m2 (A)

- 12 pcs/m2 (B)

(A) and (B): they are options.

It is noted that depending on the height or the area where these anchors will be installed, for example on a corner exposed to the wind, it may be necessary to increase the density of anchors. It will be necessary to scale and calculate each work to guarantee the optimal function of the solutions offered.

* The aspects of required minimum distance must be taken into account: 100 mm minimum base thickness, minimum distance between connectors (100 mm) and minimum distance between the connector and the base (100 mm).

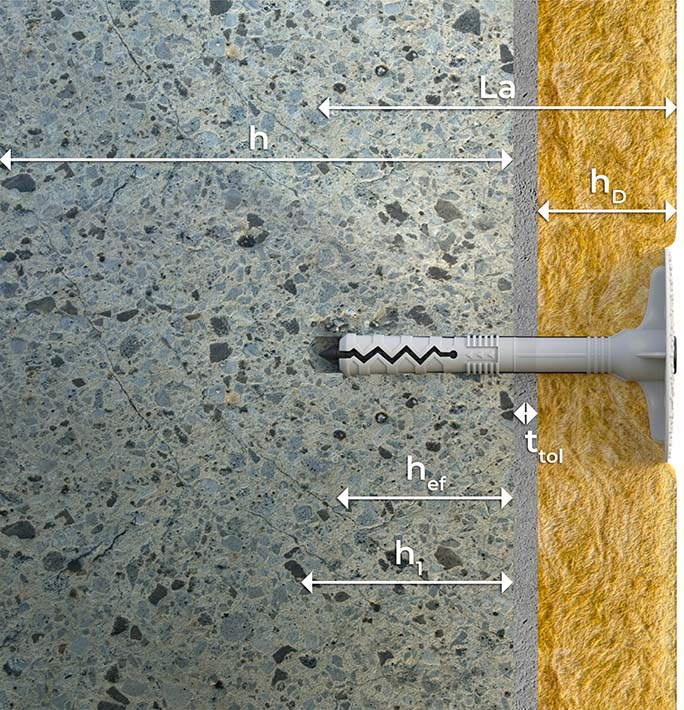

How much should the anchor measure for ETICS?

To determine the appropriate length of the anchor and the thickness to be attached, we must ascertain the following information:

Formula for calculating the total length of the anchor:

La = hD + ttol + hef

Formula for calculating the total thickness of the insulation material to attach:

hD = La - ttol - hef

The length of the anchor will be determined by the thickness of the insulation to be installed, previously ascertaining the thicknesses and construction layout present.

Use the INDEXcal calculation tool. It provides countless parameters for measuring and calculating any project, always ensuring compli nce with the standards required by approvals and certifications.

- hef: effective anchor depth

- h1: depth of the drill in the base material

- h: depth of the base material

- hD: thickness of the insulation material

- ttol: thickness of the levelling layer and/or the non-load bearing layer

Selection table

|

AIS-C

|

AIS-S

|

AIS | AIS-M | AIS-W | TE | ||

|---|---|---|---|---|---|---|---|

|

Base material

|

|||||||

| Wood | |||||||

| Metal | |||||||

|

Insulation

|

Expanded polystyrene (EPS) | ||||||

| Mineral wool (MW)* | |||||||

| Shaped polyurethane (PUR) | |||||||

| Extruded polystyrene (XPS) | |||||||

| Expanded cork | |||||||

|

Accessories

|

AIS-C | AIS-S | AIS-M | AIS-W | |||

| AIS-R | |||||||

| AIS-AM | |||||||