INDEX® Chemical Dowels

Designed to provide maximum strength, durability and safety in all applications

Polyester

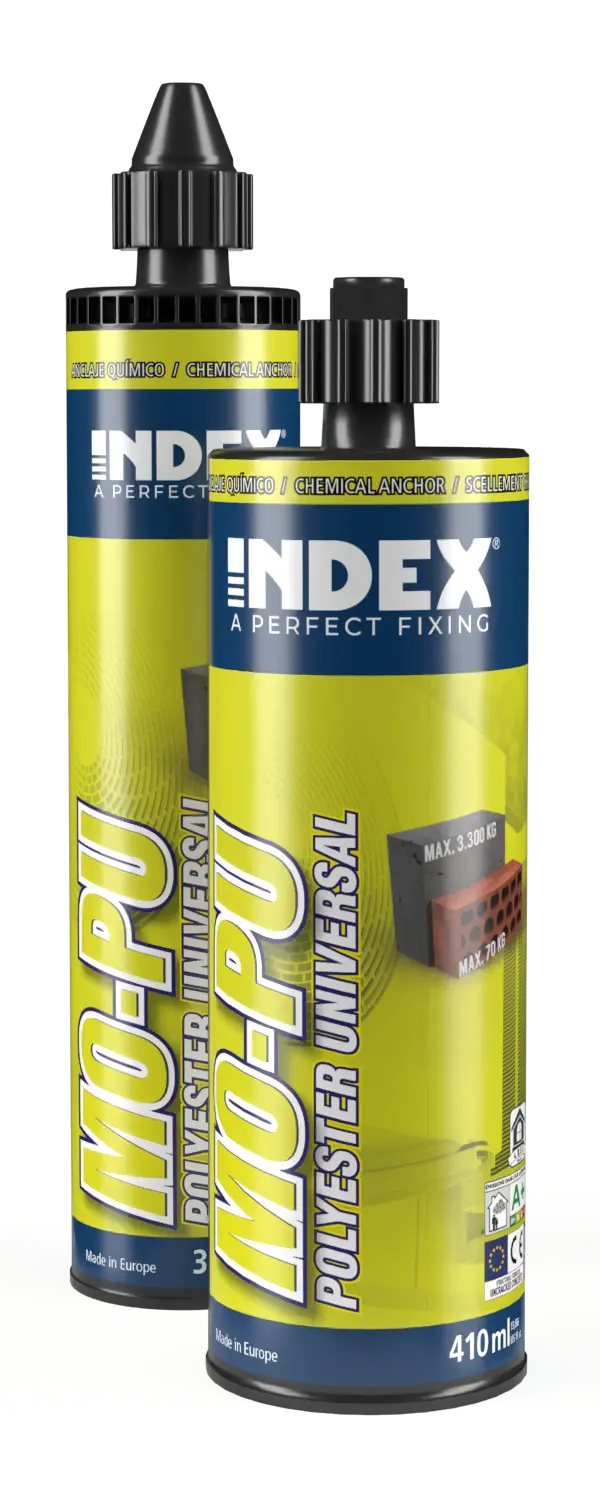

MO-PU Universal Polyester

Polyester-based chemical dowel approved for uncracked concrete. Suitable for hollow or solid masonry.

Available in a natural stone colour for a more aesthetically pleasing finish.

Applications

- For indoor and outdoor use.

- Structural applications.Rehabilitation of façades.

- Fixing of stone cladding.

- Fixing of signs and frames for air conditioning, boilers, awnings, signs, balconies, shelves, railings, etc.

Approvals

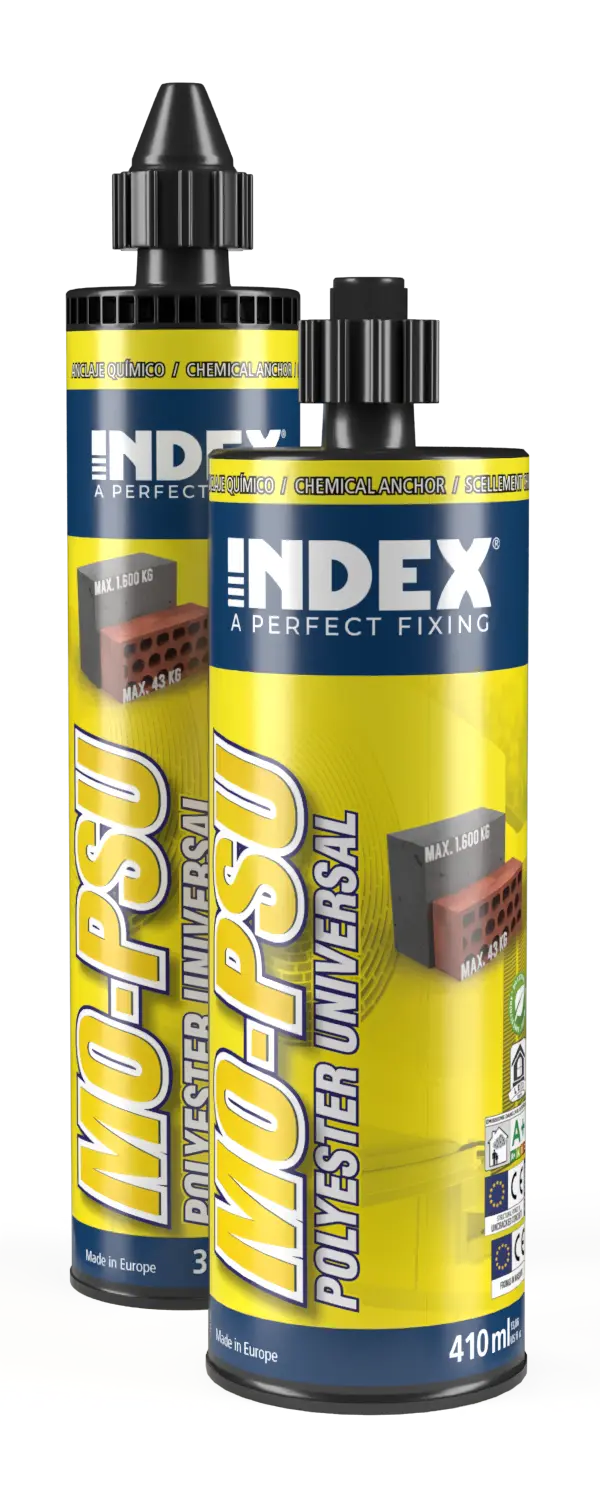

MO-PSU Universal Styrene-free Polyester

Applications

- For indoor and outdoor use.

- Structural applications.

- Rehabilitation of façades.

- Fixing of stone cladding.

- Fixing of signs and frames for air conditioning, boilers, awnings, signs, balconies, shelves, railings, etc.

Approvals

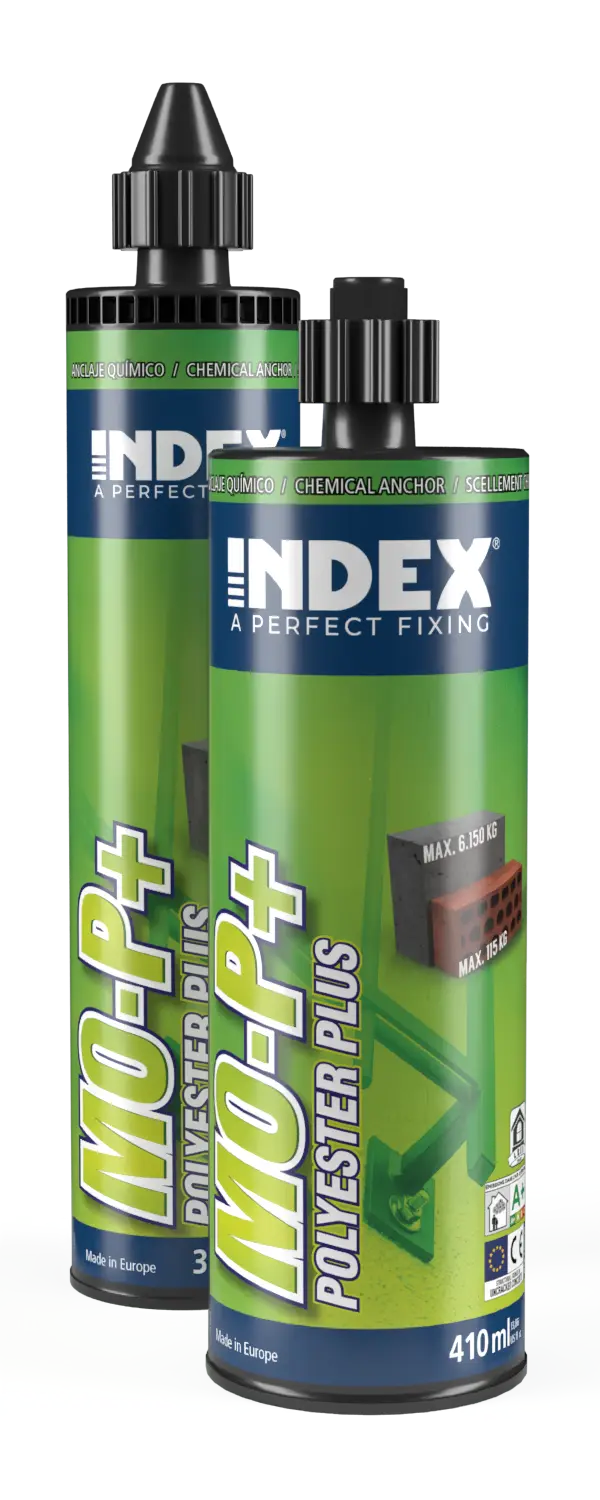

MO-P+ Polyester Plus

Applications

- For indoor and outdoor use.

- Structural applications.

- Rehabilitation of façades.

- Fixing of stone cladding.

- Fixing of signs and frames for air conditioning, boilers, awnings, signs, balconies, shelves, railings, etc.

Approvals

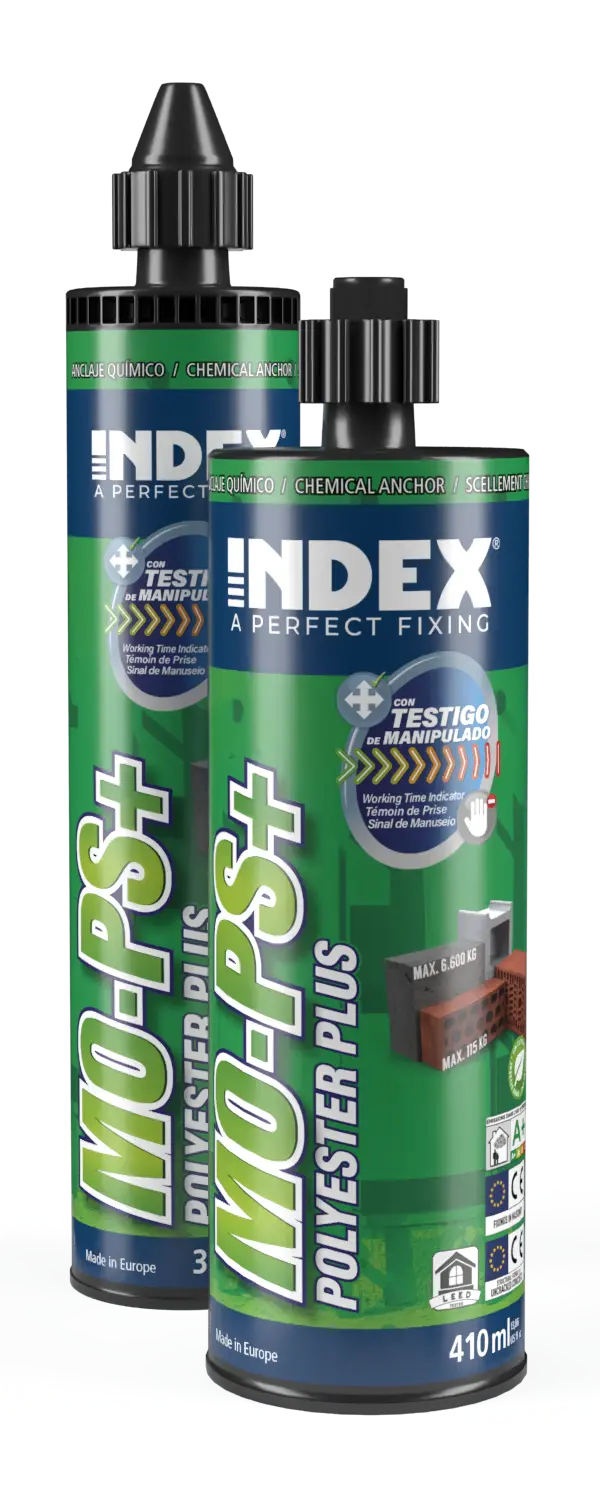

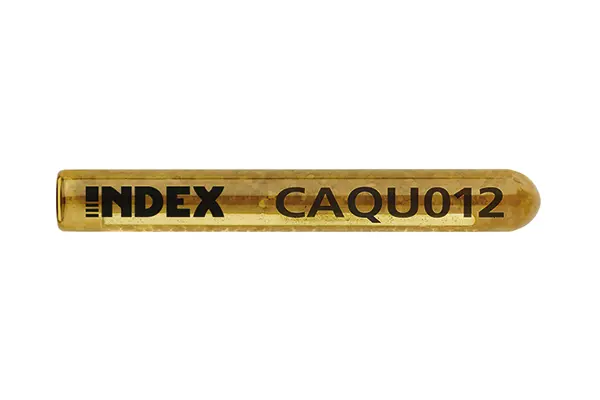

MO-PS+ Styrene-free Polyester Plus

Styrene-free polyester chemical dowel approved for all types of uncracked concrete and masonry.

It features handling indicator technology that shows when curing has started and is available in a natural stone colour for a more aesthetic finish.

Applications

- For indoor and outdoor use.

- Structural applications.

- Rehabilitation of façades.

- Fixing of stone cladding.

- Fixing of supports for air conditioning, boilers, awnings, garage door frames, signs, balconies, shelves, railings, handrails, etc.

Approvals

Vinyl Ester

MO-V Vinyl Ester

Applications

- For indoor and outdoor use.

- Structural applications.

- Fixing of traffic barriers, signs, billboards, machinery, boilers and much more.

Approvals

MO-VSF Styrene-free Vinyl Ester

Applications

- For indoor and outdoor use.

- Structural applications.

- Rebars and starter bars.

- Fixing of traffic barriers, machinery, balconies, awnings, shelves, billboards, catenary masts, security barriers, bannisters, railings and much more.

Approvals

MO-VH Styrene-free Hybrid Vinyl Ester

Applications

- For indoor and outdoor use.

- Structural applications.

- Fixings to building substructures.

- Rebars and starter bars.

- Fixing of machinery, balconies, awnings, shelves, billboards, catenary masts, security barriers, bannisters, railings and much more.

- Heavy loads and retaining walls.

Approvals

MO-VHW Winter Styrene-free Hybrid Vinyl Ester

Applications

- For outdoor use.

- Structural applications.

- Fixings to building substructures.

- Rebars and starter bars.

- Fixing of machinery, balconies, awnings, shelves, billboards, catenary masts, security barriers, bannisters, railings and much more.

- Heavy loads and retaining walls.

Approvals

Epoxy

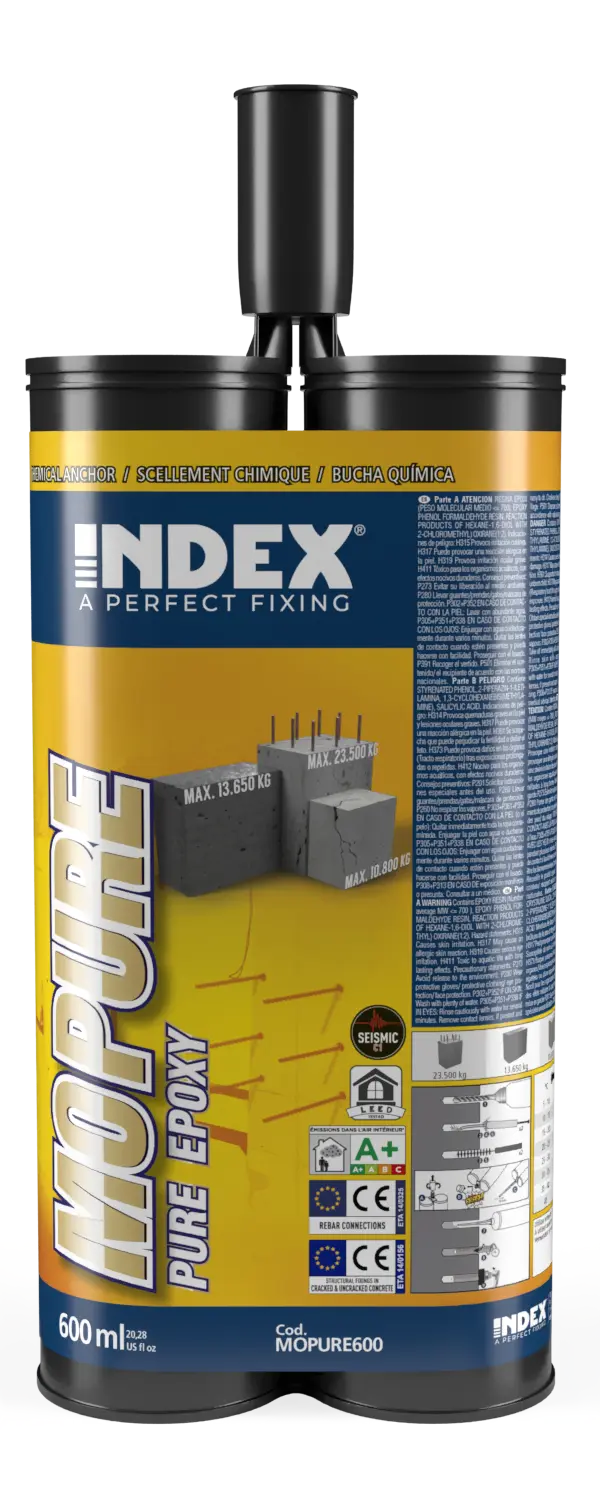

MOPURE 1:1 Pure Epoxy

Applications

- For indoor and outdoor use.

- Structural applications.

- Fixings to building substructures.

- Rebars and starter bars.

- Security barriers, retaining walls, heavy machinery, etc.

- Heavy loads and retaining walls.

Approvals

MOPUR3 3:1 Pure Epoxy

Applications

- For indoor and outdoor use.

- Structural applications.

- Rehabilitation of façades.

- Fixing of stone cladding.

- Fixing of signs and frames for air conditioning, boilers, awnings, signs, balconies, shelves, railings, etc.

Approvals

Chemical resin anchors for high-strength fixings in a wide range of materials

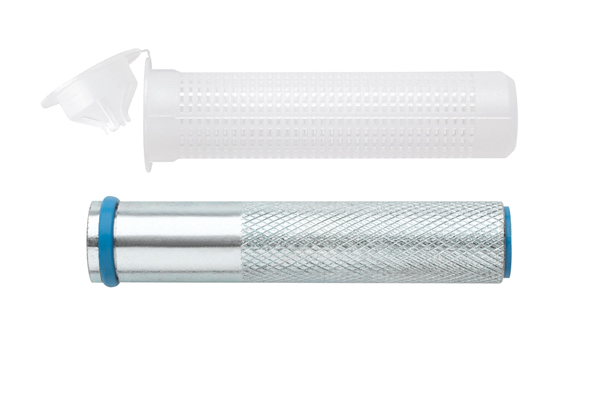

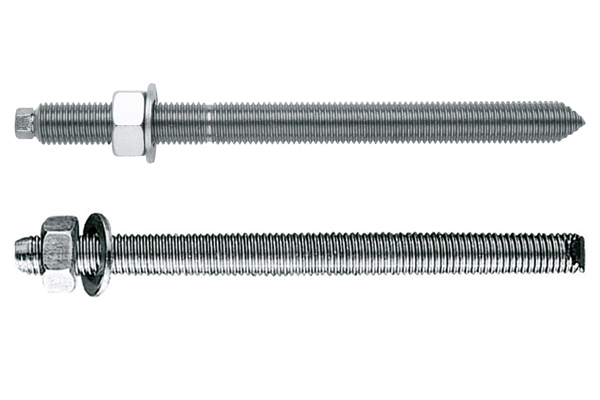

Chemical resin anchors are one of the most popular products for fixing elements to different materials both in professional and DIY applications.

They act like a glue between the base material and the element inserts, and they are used to fix heavy loads to dense materials, such as concrete or stone, and hollow materials, such as stonework or hollow bricks.

High Load-bearing Strength

They distribute the load uniformly across the fixing, preventing the emergence of pressure points and providing increased load capacity compared to mechanical anchors. This enables extra-strong, secure fixings.

Ease of Installation

They make it possible to provide the fixing strength required by the load. If you need to support a heavier load, you can drill a deeper or wider bore hole to apply more resin.

No Pressure Points or Cracks

Since these anchors rely on adhesion, they do not generate pressure points or cracking on the surface around the fixing. This makes it possible to install fixings close to edges and in reduced spaces between anchors while ensuring stability and durability.

How to Install a Chemical Anchor

Consigue una instalación segura, resistente y duradera

Learn with Us

In this video, we explain what the different types of chemical anchors are, how to choose the most suitable one for your material and load requirements, and how to apply each type correctly by following the instructions on the technical datasheet.