Certain mechanical anchors, especially bolt-through threaded anchors or concrete screws, may be approved for installation at different depths. This possibility involves considering several details regarding their installation conditions and performance.

First, this means that we can install the same anchor at two or three different depths, and we will use an example to illustrate this. For this purpose, we will take an MTH M12 x 110 anchor (AH12110) under the following conditions, as a reference:

- Uncracked concrete, C20/25 class

- Separated from other anchors

- Separated from the edges of the concrete element

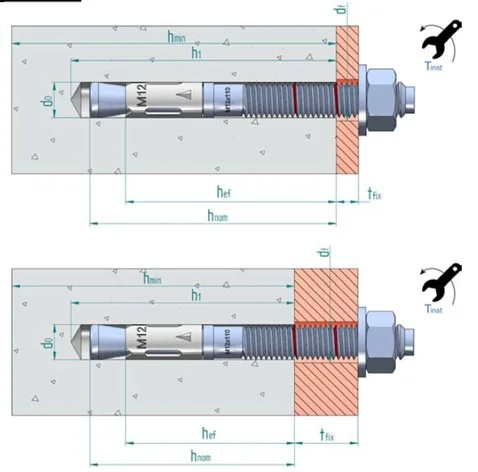

In this anchor we can visually check for two red marks painted on the threaded shaft. For more information Bolt-through anchor depth marko. These marks indicate the anchor installation depth; the presence of two marks indicates that the anchor has two approved installation depths.

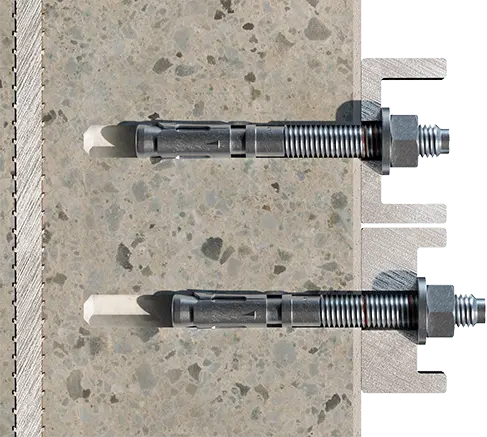

The following pictures show the installation of this product at each of the two approved installation depths. The deeper of the two is referred to as the “standard installation depth” and the other one is referred to as the “reduced installation depth”. For any approved anchor with three installation depths (TH/TF Ø6 and Ø10), the one between the standard and the reduced depths is called “intermediate installation depth”.

In any case, there are certain technical aspects to be considered in relation to the performance of the product:

- Different resistance levels

An installation depth that is shallower than the standard installation depth as indicated above will always lead to lower resistance values. This is because introducing the anchor at a shallower depth into the base material (concrete) means that the anchor has less material to transmit the load to, and therefore it usually offers a lower resistance to the loads it is subjected to. This reason for this is that the effective depth of the anchor has a direct influence on the concrete cone strength of the anchor. In the example mentioned above, the maximum recommended tensile strength at standard depth is 12.58 kN, while at reduced depth it is 8.28 kN. - Capacity of fixing thicker elements

One of the advantages of having an approved anchor with various installation depths is the possibility of fixing panels with different thickness values using the same anchor. In our example, the anchor would be able to fix an 18-mm-thick panel if installed at standard depth, while at reduced depth this thickness could be increased to 33 mm. - Edge distances and spacing

Another advantage of an approved anchor with various installation depths is that critical values, such as edge distances and spacing, are reduced when the anchor is installed at shallower depths. This not only allows us to install the anchors closer together but also closer to the edge without compromising their performance. In our example we see that at reduced depth the Scr,N/Ccr,N value would be 150 / 75 mm, while at standard depth it is 195 / 98 mm. - More affordable solution

The most interesting advantage for the user, economically speaking, is the possibility to use shorter anchors to fix panels if they can support the applied load. If a user wanted to fix a 15-mm-thick anchor plate, instead of using the chosen example (AH12110) and installing it at standard depth, we could choose a shorter anchor (AH12100) and install it at reduced depth, since it has a maximum fixing thickness of 23 mm in these circumstances.

In short, an anchor with more than one installation depth allows the user greater flexibility in terms of strength, thickness of the material to be fixed, edge distances and spacing than an anchor with a fixed installation depth.

Latest revision: FAQ14 rev0