Users and installers tend to confuse the operating principles of threaded elements such as bolts, screws and studs with post-installation male-thread anchor bolts. (MT range anchors are examples of these). As a result, we often come across situations which require “8.8 quality anchors”. Here we can see how each product functions depending on its type:

Threaded elements, often referred to as bolts, tend to be classified on the basis of their mechanical properties. They are screwed into nuts or threaded holes in metal components. In line with the EN-ISO 898-1 standard*, the classification used to differentiate such elements makes reference to the “steel grade”, of which the most common are 4.8, 5.8, 6.8, 8.8 and 10.9.

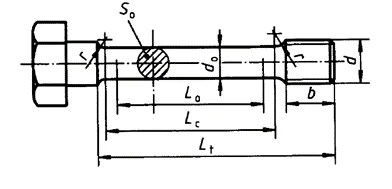

The classification mentioned above comes from this standard. In this system, the first number refers to the ultimate tensile strength (fub) expressed as N/mm2 and multiplied by 100. The second number is the percentage at which the yield strength is reached (fyb), also expressed as N/mm2. Screws usually have a steel grade of 8.8, this effectively means

fub= 800 N/mm2 is the ultimate tensile strength.

fyb= 80% de 800 = 640 N/mm2 corresponds to the yield strength.

The final values will depend on the area of the bolt – the strength of an M6 bolt is naturally not the same as in the case of an M24 bolt. If the bolt breaks or there is some other failure, this will occur on the shaft and will depend on the cross-section and steel grade. As these elements are used to join metal parts, this is the most important characteristic when measuring strength.

This approach to measuring the strength of a threaded element is widely used in the sector and is at the forefront of the minds of users and designers.

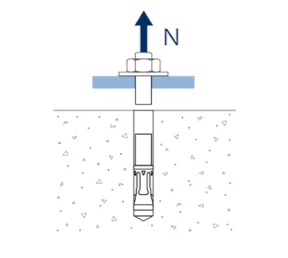

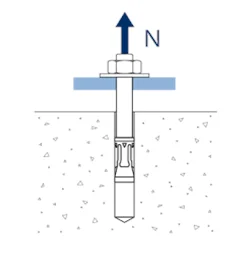

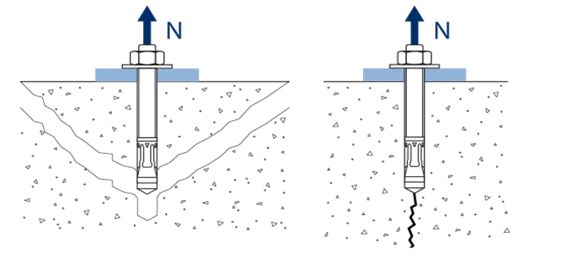

In the case of anchors, and more specifically those anchors where the functional principle is friction and expansion is the result of torque-controlled expansion (as is the case with male-thread anchor bolts) this does not work in the same way.

The first thing to be taken into account is that a mechanical anchor may fail for any of the following reasons when the problem is the result of failure under tension loads:

Steel failure

Pull-out failure

Concrete cone or splitting failure

For an anchor to fail due to one of these three reasons, the load must be greater than the strength of the anchor in the failure type in question. Let us take the case of steel failure. As we have seen previously, the strength of a threaded element depends on two factors, the steel grade and its diameter.

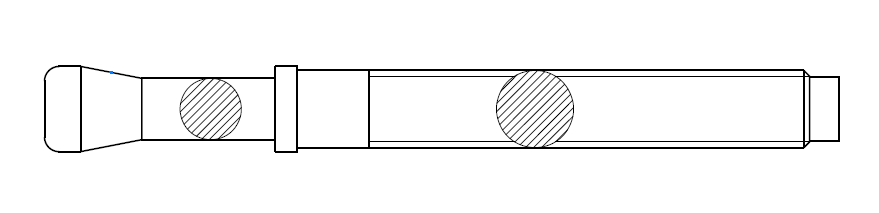

- Firstly, the steel grade. As a consequence of the cold manufacturing process, this strength is not uniform throughout the shaft, as by reducing the cross-section at the neck which houses the expansion clip, strength is increased due to the work hardening of the material.

- Meanwhile, the diameter of the shaft is not constant along its length, as the neck area is weaker.

Typically, steel failure occurs at the neck before it does in the threaded section of the shaft.

In any event, in MT anchors, resistance to pull-out failure and concrete cone tends to be less than in the steel itself, and therefore is not a relevant factor in terms of the anchor’s properties.

Finally, steel strength in the case of male-thread mechanical anchors is determined in the testing carried out during the approval process, details of which are given in the corresponding European Technical Assessment (ETA). If you wish to check these values, proceed as follows:

- Open the approval document corresponding to the product in question.

- Search for the “STEEL FAILURE” part of the section on “Tensile strength”. There you will find the pertinent values, as well as the corresponding partial safety factor.

For example: MTH

| MTH: ZINC-PLATED ANCHOR | Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| M6 | M8 | M10 | M12 | M14 | M16 | M20 | |||

| STEEL FAILURE | |||||||||

| NRk,s | Characteristic strength | [kN] | 7.4 | 13.0 | 23.7 | 33.3 | 49.1 | 60.1 | 99.5 |

| yM,s | Partial safety factor | [-] | 1.40 | 1.40 | 1.40 | 1.40 | 1.40 | 1.40 | 1.40 |

* Mechanical properties of fasteners made of carbon steel and alloy steel – Part 1: Bolts, screws and studs with specified property classes – Coarse thread and fine pitch thread (ISO 898-1:2013).

Latest revision: FAQ3 rev0