Wood screws

Wood, like any other material, has specific characteristics that make it advisable to use certain types of screws when working with it. There are different alternatives available when securing items to wood. Which you choose depends on factors like the type of wood you’re working with, joint requirements or whether it’s for indoor or outdoor use. Before selecting the most appropriate screw, it’s vital that you familiarise yourself with its particular characteristics and uses.

Types of coating for wood screws

Materials have improved with the passing of time in response to the need to become increasingly more resistant to adverse environments, corrosion and rust. There are special screws for wood that are made from materials like A2 stainless steel. This type of screw is particularly recommended for outdoor use, while bichromatic or zinc-plated ones greatly enhance corrosion resistance.

Another important factor to bear in mind when opting for one material or another is the aesthetic finish sought. For instance, the colour of bichromatic screws is ideal to conceal their presence when used in wood.

Thread types

Both self-tapping screws and other wood screws are threaded, but they don’t all have the same thread size. Those with a thread along the entire body of the screw enter the material to be secured completely. This is ideal for securing thin metal pieces, such as metal plates, to wood. Others are only half-threaded, which make them the perfect choice for securing thicker parts to wood.

Head types of screws for wood

As is the case with all types of screws, the head is a key feature when it comes to choosing the most appropriate screw. It influences how the screw will look after having penetrated the base material. For instance, to fit elements on which the screw head will be flush with material to which it is screwed, it is important to use a wide headed screw to ensure greater pressure on the material. Our short TEX family specially designed the fixing of iron, for which a perfect flush fit is required, falls into this group.

The screws may be hexagonal, flat, or socket-headed amongst others.

Screw drive types for wood

The screw drive or slots are another important feature to be taken into account depending on the type of work to be carried out. INDEX wood screws mainly come with Pozidriv and Torx drives. The Pozidriv has eight contact points thereby ensuring a tight fit to the surface, which makes them perfect for work requiring a strong hold. On the other hand, the Torx drive has a six-point, star-shaped drive, which also provides a high degree of resistance. Amongst the range of Torx drive screws, there are tamper-proof ones, which are characterised by having a special, pin-like protrusion in the drive that protects them from manipulation by third parties.

The screw head and drive dictate the tool be used, which in turn directly impacts on the tightening torque.

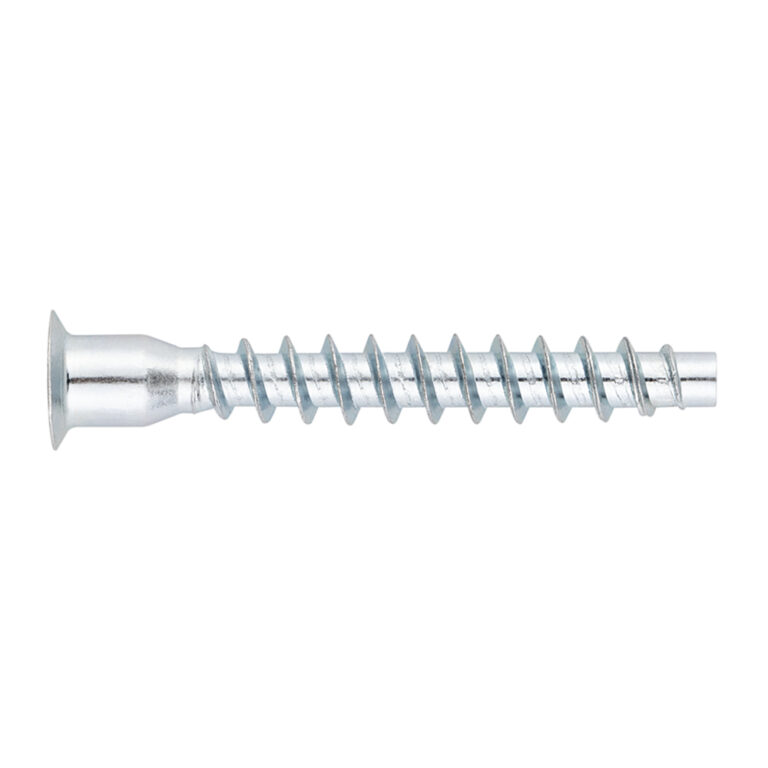

Our TEX range: high-performance self-tapping screws

Our high-performance TEX self-tapping screws do not require any prior drilling, which means the wood suffers less splitting. They are quick and safe to use and enable perfect fixing to any surface.

These screws are mainly used for:

– Installation of items on wooden surfaces.

– Securing iron fittings to wood, the joining of wooden parts and the reinforcing of wood with metal, amongst other uses.

– Joining wooden surfaces where the screw must be fitted near the edge.

Moreover, they have four basic characteristics that make them unique:

1. Their threads enable maximum precision during installation.

2. They are self-cleaning, which helps to remove the shavings when being screwed in.

3. As they are sharp-tipped, they enable screwing without the need for any prior drilling.

4. As they are self-countersinking, they allow for a perfect finish.

We have five different versions of these screws, in terms of both their drive and plating, so you can choose the best one to suit your needs. Their characteristics and properties make them the perfect solution for use on wood.