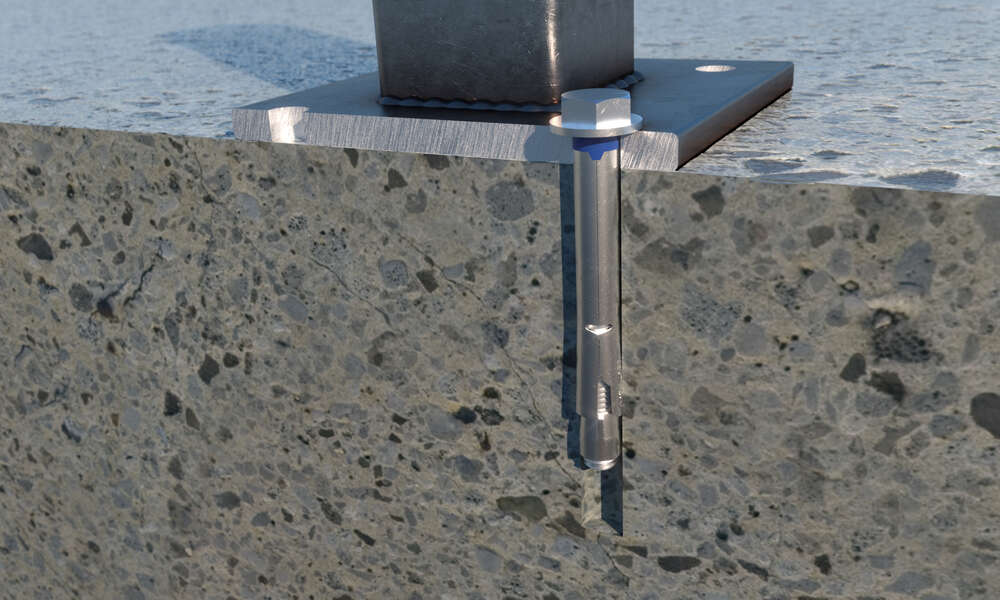

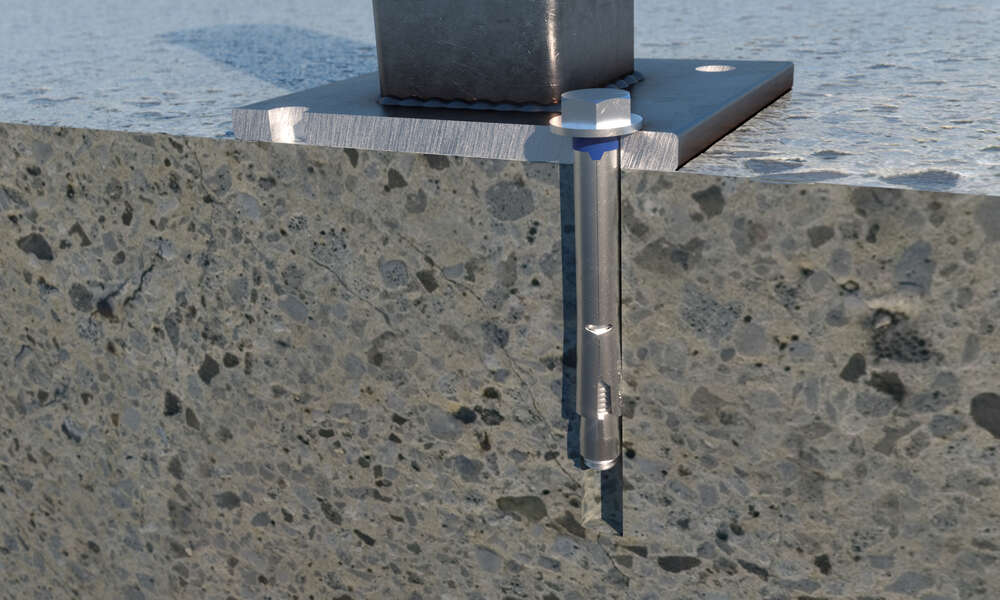

Anclaje antigiro para cargas medias con tornillo hexagonal y principio de funcionamiento por expansión en materiales macizos. Ha sido diseñado y patentado por INDEX para ofrecer anclajes seguros gracias a sus componentes anti giros incorporados en el casquillo, la camisa y el cono, lo que permite que el anclaje no rote con el apriete.

Se trata de un anclaje perfecto para realizar fijaciones estructurales en hormigón no fisurado. Cuenta con una homologación de la Comunidad Europea que garantiza su total compatibilidad con este tipo de fijaciones estructurales.

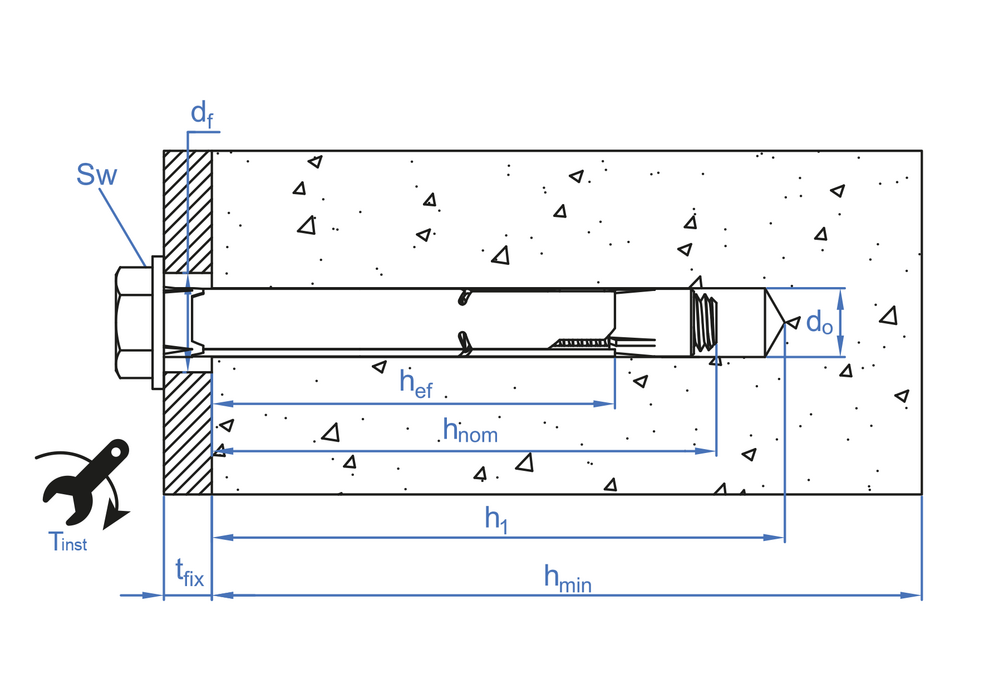

Entre las características que dotan a este anclaje de esas prestaciones, destaca su nuevo diseño con apertura en la camisa, que optimiza la entrada del cono y facilita su expansión. El cono cuenta también con aletas antigiro para asegurar una correcta instalación y evitar la rotación del anclaje durante la instalación. La expansión del anclaje asegura que el ajuste al material sea más fuerte; cuenta con un troquel en la camisa que facilita esta expansión. La cabeza del anclaje cuenta con una arandela que aumenta la superficie de fijación y una goma azul que también evita el giro. Para facilitar la instalación, esta pieza incluye una marca para indicar cuál es la profundidad óptima de instalación. Está indicado para realizar anclajes seguros en materiales como hormigón, hormigón armado, piedra o ladrillo macizo, en aplicaciones estáticas o casi estáticas como la fijación de señales, estanterías, paneles, pórticos, barandillas, toldos, postes de vallas, mobiliario urbano o asientos de cines, teatros y estadios.

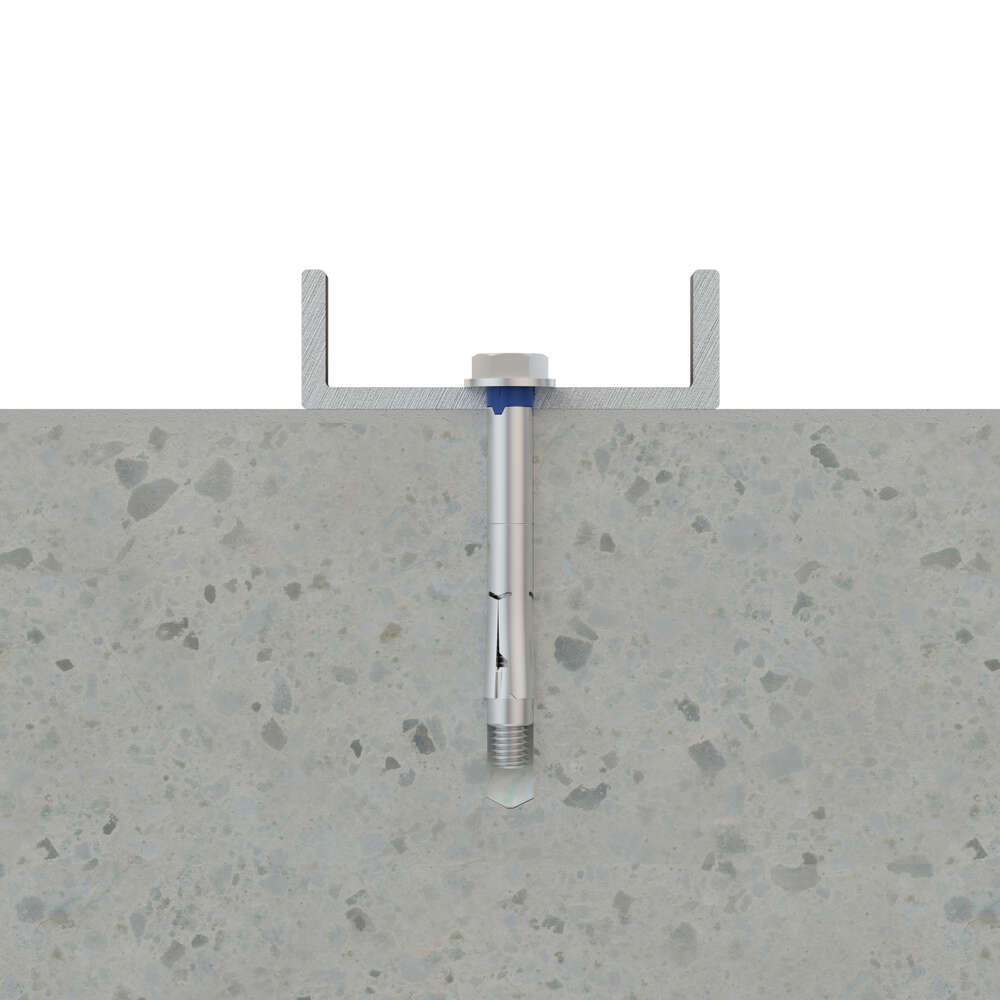

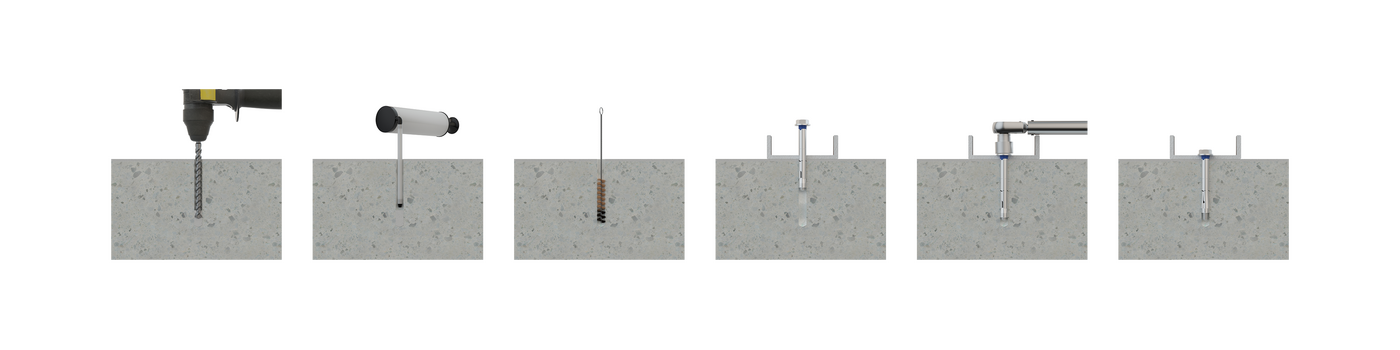

Este anclaje está fabricado en acero cincado, un material de gran resistencia con un recubrimiento superficial de zinc que aleja la corrosión y el óxido. La instalación de este anclaje es sencilla, se comienza con el taladrado, en el que este anclaje es admisible en taladros secos, húmedos o inundados. Una vez que se ha realizado el taladrado con el diámetro y la profundidad necesaria es necesario insertar el anclaje hasta que la cabeza quede enrasada con la superficie del material a fijar y utilizar un martillo en caso necesario. La instalación se debe hacer a través del material a fijar.

La calidad de los materiales con los que está diseñado, su diseño patentado y su homologación, hacen que este anclaje sea perfecto para aplicaciones profesionales seguras y resistentes.

[FUNCIÓN ANTIGIRO] Anclaje antigiro para cargas medias con tornillo hexagonal y principio de funcionamiento por expansión en materiales macizos. Cuenta con varios elementos antigiro (cono, camisa y goma) que permiten que el anclaje no gire cuando se comienza a instalar, facilitando la instalación y garantizando una óptima expansión y rendimiento.

[APLICACIONES MUY VARIADAS] Indicado para realizar anclajes seguros en aplicaciones estáticas o cuasi estáticas como la fijación de señales, estanterías, paneles, pórticos, barandillas, toldos, postes de vallas, mobiliario urbano o asientos de cines, teatros y estadios.

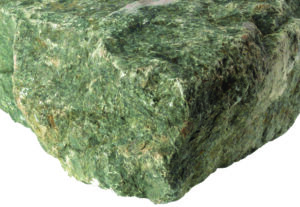

[HORMIGÓN Y OTROS MATERIALES] Idóneo para fijaciones sobre materiales macizos como hormigón, hormigón armado, piedra o ladrillo macizo.

[CALIDAD ASEGURADA] Fabricado en acero con recubrimiento cincado, un material de gran calidad y resistencia que asegura anclajes sólidos y seguros en ambientes interiores o exteriores de baja humedad.

[HOMOLOGACIÓN EUROPEA] Diseño patentado por INDEX A Perfect Fixing y con homologación ETA 18/0018 para usos no estructurales en hormigón.