When choosing the types of plugs for hollow walls it is essential to consider aspects such as the base material where the fixing is going to be made, the loads to which it is going to be subjected, the construction layout where the anchor is going to be installed, etc.

Our catalogue includes a wide selection of anchors to choose from to face all kinds of applications, even the most demanding ones. We have references of different materials, suitable for hollow and solid surfaces and for fixing loads of different weights.

Types of hollow wall plugs according to the principle of operation

One of the factors to consider when choosing the right plug is the way in which it is fixed to the base material.

Chemical anchors

They are a versatile and widely used solution for fixing large loads to solid and hollow materials with guarantees. They ensure a resistant and lasting union of elements such as iron fittings, beams, urban furniture, air conditioning supports, façade fixings in both hollow and solid material, façade renovation, etc.

To carry out this type of fastening safely, the hole where the fastening is to be made must be properly cleaned and the handling and curing times must be respected before applying the load.

For this application we recommend the use of MO-PS+ mortar, with European ETE approval.

Plastic expansion plugs

Plastic expansion plugs are those that expand inside the base material, securing the fixing. This type of wall plugs is suitable for both hollow materials, through expansion, and solid materials, where they are knotted on the back of the base material as the screw is inserted, facilitating fixing.

The 4-segment plug TN4S is suitable for low loads and should be used with the bolt recommended in the technical documentation.

For higher loads, the plastic plug T-NUX is available with a special screw for use in concrete, solid, perforated and hollow bricks, concrete blocks and aerated concrete, and is ETE-approved for use in concrete.

Nail-in or slam-in anchor plugs

The tap-in plugs allow for quick and easy fixings. The screw and plug are pre-assembled, which allows for quick installation by simply placing the plug in the drilled hole and tapping it into the screw.

Examples of tapping plugs are the TCCA plug (countersunk head), TCCC (cylindrical head) or TCSP (with wide head).

They are mainly used for solid materials, but can also be used in hollow brick, especially the TCSP model.

Self-drilling metal plugs

These are those that do not require drilling prior to installation and are designed for fixing light elements to plasterboard walls. Their principle of operation consists of screwing the plug directly into the panel and then screwing the screw into the panel. This type of fixing is a quick solution for light loads.

There are several models manufactured in zamak (TAPLAME and TAPLA ZK) and nylon (TAPLANY).

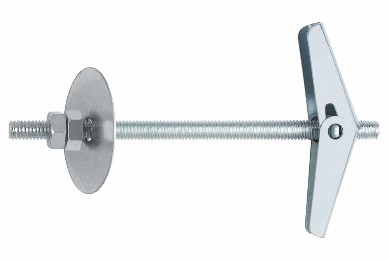

Gravity tipping or tilting plugs

Gravity tilt plugs are used to anchor objects such as lamps or posters in false ceilings made of plasterboard, plaster and hollow concrete blocks. They consist of a movable head that functions as a stop inside the base material and a hook or dowel to fix our lamp or any other light element.

Examples of this type of anchor would be the BA-ES (tilting anchor with plug) or the BA-GA (tilting anchor with plug). There is also a version of the plastic strip swivel, BANYM in M5 and M6, which makes fixing even quicker and easier.

Choosing the right hollow wall plugs is essential to ensure a secure and durable fixing. With a wide variety of options available, from chemical anchors to self-drilling plugs, it is crucial to select the correct type depending on the base material and load required.

And, as always, be sure to follow the manufacturer’s recommendations for a successful installation.