Standard EN 1992-4, which is part of Eurocode 2, covers the calculation of anchors for use in concrete. In this context, the difference between cracked and non-cracked concrete is crucial for the selection and dimensioning of anchors.

What is cracked concrete?

Cracked concrete is concrete in which cracks may appear under service load. This is common in structural elements subjected to bending, tensile or torsional loads, where cracks may develop due to internal stresses.

Design requirements for anchorages in cracked concrete

It is assumed that cracks may be present in all possible directions. This could be due to external loads, concrete shrinkage or thermal changes. Anchors designed for cracked concrete are prepared to function safely even if there are cracks in the surrounding material.

Anchors in cracked concrete must meet more stringent requirements to ensure that they maintain their load-bearing capacity and stable behaviour, even in the presence of cracks.

What is non-cracked concrete?

Non-cracked concrete is concrete in which no cracking is expected to occur under normal service conditions. This can occur in structural elements that are mainly subjected to compression, where the possibility of cracks developing is minimal.

Design requirements for anchorages in non-cracked concrete

This type of concrete is generally associated with predominantly compressive loads, where the internal stresses do not exceed the tensile strength of the concrete.

Anchors in non-cracked concrete are designed on the assumption that the concrete surrounding the anchor will not crack. Therefore, the design criteria are less demanding than those for cracked concrete.

Implications for anchor design

Load-bearing capacity

Anchors in cracked concrete generally have a lower load-bearing capacity or require larger safety margins than those used in non-cracked concrete.

Type of anchors

Some anchors are specifically designed for cracked concrete, offering features such as increased tensile strength in the presence of cracks. In contrast, other anchors can be used in non-cracked concrete where cracking is not expected.

For this purpose, the European Assessment Document provides a system for assessing anchor performance according to 12 options.

The first 6 options (1 to 6) cover performance in cracked and non-cracked concrete while the last 6 (7 to 12) cover performance in cracked concrete only. Within each group, each option determines the performance under different circumstances, with options 1 and 7 being the most popular as they provide more information on the anchor’s performance under different circumstances.

See table below:

| Option | Cracked | Non-cracked | Single resistance value for all concrete strength classes | Specific resistance value for each concrete strength class | Single resistance value for all load directions | Differentiated tensile and shear strength | Reduction values for distances between anchors and at the edge of the concrete | Design method according to prEN 1992-4 |

| 1 | ✓ | ✓ | X | ✓ | X | ✓ | ✓ | A |

| 2 | ✓ | X | ||||||

| 3 | X | ✓ | ✓ | X | B | |||

| 4 | ✓ | X | ||||||

| 5 | X | ✓ | X | C | ||||

| 6 | ✓ | X | ||||||

| 7 | X | ✓ | X | ✓ | X | ✓ | ✓ | A |

| 8 | ✓ | X | ||||||

| 9 | X | ✓ | ✓ | X | B | |||

| 10 | ✓ | X | ||||||

| 11 | X | ✓ | X | C |

Let’s look at the following example:

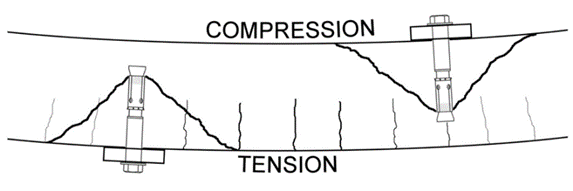

What usually happens is that one side of the concrete is subjected to stresses from compression while the opposite side is subjected to tensile stresses (tension). This may vary depending on the arrangement of the building structure and must be verified by an engineer with expertise in anchoring and in working with concrete.

- Theoretical example:

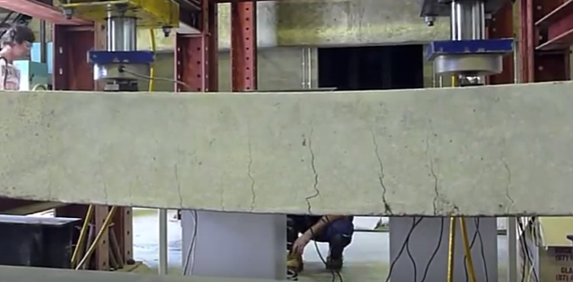

- Real-life example: