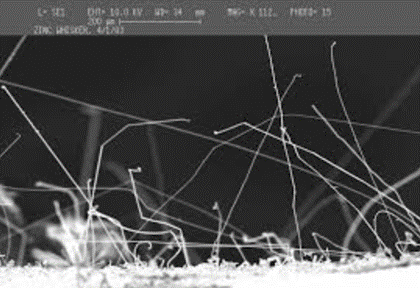

Zinc whiskers, also known as zinc whiskers, are microscopic filaments that appear on materials that have undergone a zinc plating process, especially when steel is coated to protect it from corrosion.

During zinc plating, the zinc is subjected to high pressure to achieve adhesion to the material. Once the process is complete, this pressure is released, forming small crystalline-microscopic zinc filaments which, over time, can grow to several millimetres and become visible to the naked eye.

These filaments are brittle and easily detachable. This phenomenon also occurs in hot-dip galvanised coatings.

Zinc whiskers are not affected by humidity or temperature and their growth cannot be stopped or controlled by changes in ambient environmental conditions.

A silent threat in data centres

Zinc whiskers are a threat in data centres as they can detach for a variety of reasons and cause serious problems. The main sources of whisker detachment are:

- Air conditioning systems: the air that circulates to maintain a stable temperature in servers and prevent failures can also pull the zinc filaments out and transport them to chips or motherboards, which can cause short circuits.

- Maintenance and use: when performing maintenance, cleaning or manoeuvring to access servers, cables are moved and can cause shocks that generate vibrations, causing the zinc whiskers to detach from the base material.

In addition, data centres often have technical metal floors, such as tramex, or metal supports to access the cabling underneath, where zinc strands are also formed and can be easily dislodged by any vibration caused by maintenance or personnel traffic.

How do you know if there are zinc whiskers in a data centre?

In these cases, zinc whiskers are difficult to detect with the naked eye, due to their microscopic size. Until the failure occurs and is diagnosed, it is very easy to believe that there is no trace of them in the data centre.

Some indications of their presence are:

- Random short circuits in any electrical element present in the room.

- Increased short circuits when maintenance work is being carried out or when floors are being moved.

To avoid these problems, our recommendation is to use zinc-nickel finished fasteners on all carbon steel items that require coating. In our catalogue you can find the GP-Z, GP-G and GPX profiles for heavy loads.