The different technical aspects of mechanical and chemical anchors installed in concrete are outlined below. We identify different situations in which a correctly installed anchor may fail and explain the main failures it may suffer and why they occur.

During the calculation and verification process, it is important to check that the installation is sufficiently strong to withstand the following situations:

According to the loads to which the anchors are subjected, the failures have been divided into those to which a tensile load is applied (force applied along the axis) and those to which a shear load is applied (force applied at right angles to the axis). It is only necessary to check these categories in case of combined tensile and shear loads

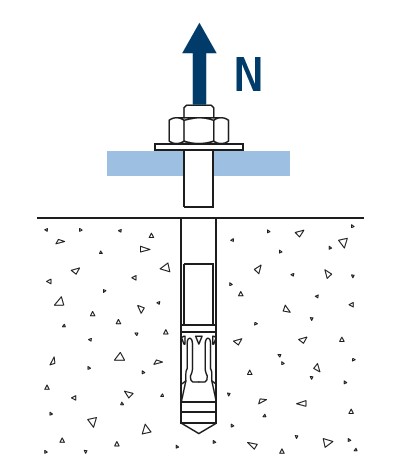

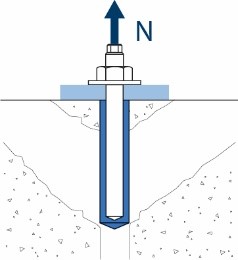

TENSILE LOAD

1. Steel failure

Failure mode characterised by fracture of the metal part of the anchor. Occurs when an anchor is subjected to a tensile load exceeding the strength of the steel. The failure usually occurs in the area with the smallest cross-section. In the case of male threaded anchors, the breakage occurs in the area of the clip; part of the anchor will remain inside the installation hole, breaking off above the clip.

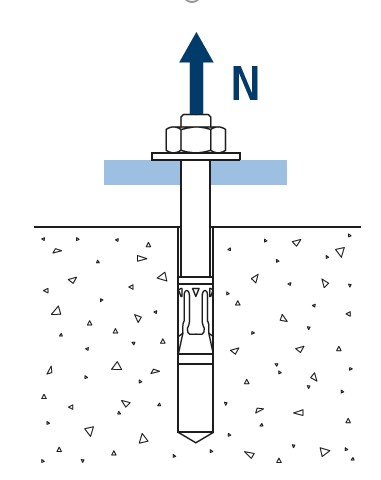

2. Pull-out failure

Failure mode characterised by the anchor body being pulled out without the full strength of the concrete being reached. Occurs when the tensile load applied to the anchor exceeds the frictional or fixing force between the fixing mechanism and the inner face of the concrete, resulting in the complete extraction of the anchor. In the case of male threaded anchors, the clip usually remains inside the hole and the shaft is fully extracted. This type of failure only applies to mechanical anchors.

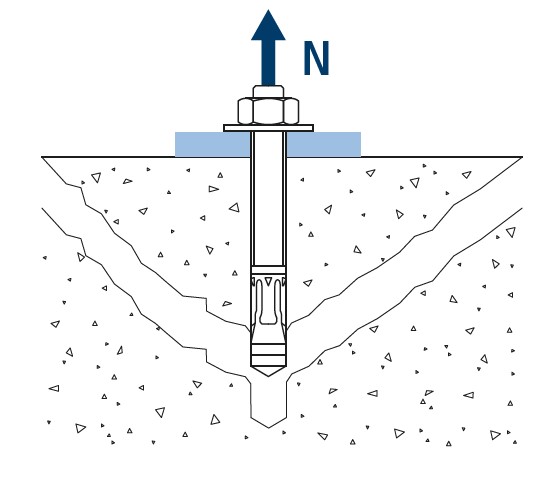

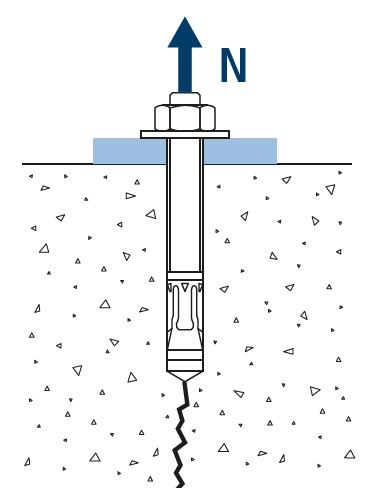

3. Concrete cone failure

Failure mode characterised by concrete breakage. Occurs when the tensile load to which the anchor is subjected is greater than the strength of the concrete, resulting in a breakage of the base material in the form of an inverted cone. This failure is directly related to the depth of installation and the strength class of the concrete.

4. Combined pullout and concrete cone failure (chemical anchors)

A failure mode characterised by the failure occurring at the interface between the bonded material or mortar and the base material, or between the bonded material and the metallic element (adhesion failure) and which, in addition, contains a small cone of concrete at or near the top of the concrete surface. Occurs when the tensile load to which the chemical anchor is subjected exceeds the adhesion strength. This type of failure only applies to chemical anchors and its verification does not exempt the verification of the other types of failure.

5. Splitting failure

A failure mode characterised by the concrete fracturing along the plane passing down the axis of the anchor(s). In these cases, a crack in the base material causes the anchor to lose its holding power. Occurs when the tensile load to which the anchor is subjected exceeds the strength of the concrete under particular circumstances. It only needs to be verified when the distance to the edge of the concrete element is less than the critical splitting distance (scr,sp) in the case of a single anchor or 1.2 times the critical splitting distance in a group of anchors.

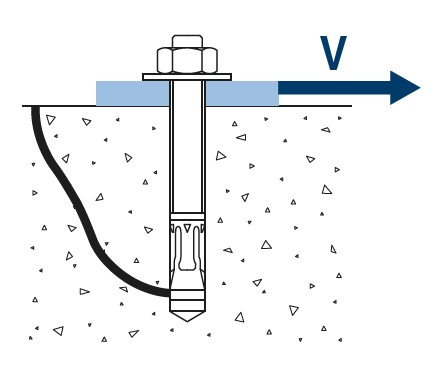

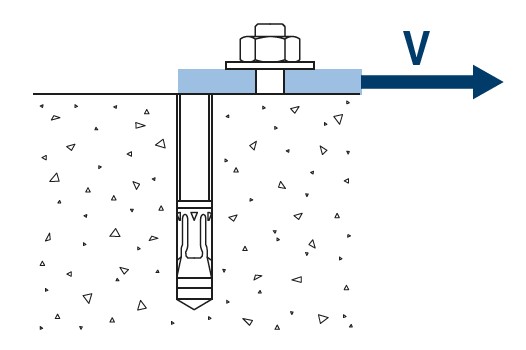

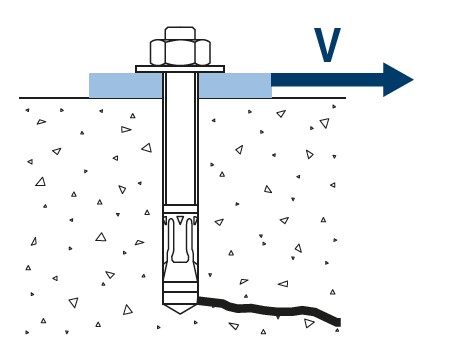

SHEAR LOAD

1. Steel failure without lever arm

Failure mode characterised by fracture of the metal part of the anchor. Occurs when an anchor is subjected to a shear load greater than the strength of the steel. Failure usually occurs in the area of the anchor which is flush with the surface of the base material. In the case of male threaded anchors, the breakage occurs in the threaded area.

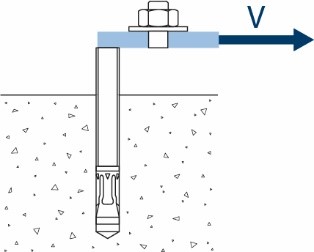

2. Steel failure with lever arm

Failure mode characterised by fracture of the metal part of the anchor by bending. Occurs when an anchor is subjected to a shear load greater than the resistance of the steel to bending. The main difference to the failure without lever arm is the offset between the surface of the base material and the anchor plate. This creates a bending moment.

3. Concrete edge failure

Failure mode characterised by breakage of the concrete edge. Occurs when the shear load to which the anchor is subjected exceeds the strength of the concrete edge, causing the concrete to break between the edge of the concrete and the anchor.

4. Pry-out failure

A failure mode characterised by a crack forming in the concrete in the opposite direction to the direction of application of the shear load. Occurs when the shear load to which the anchor is subjected causes a cracking in the neutral zone of the base material from which the shear stress is applied which cancels the anchor’s holding capacity.