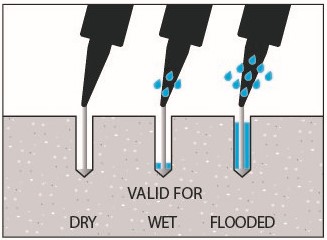

There are some situations where anchors have to be installed underwater or where they are subsequently covered by water and submerged. However, these are specific cases which do not represent general applications. Below, we will see how different chemical anchors behave in this situation, according to their respective types.

Before continuing, please take a look at FAQ B.2 What is the difference between dry, wet and flooded holes? What impact does this have on the performance?

Once you have understood the difference between dry, wet and flooded holes, you are in a position to understand the following information:

Chemical anchors: In the case of chemical anchors, their suitability for installation must be verified based on the condition of the hole (dry, wet or flooded). This may also affect the handling and installation time; we always recommended that you consult the relevant European standards. In the case of chemical anchors, the viscosity of the products involved makes it more difficult. This is why INDEX does not currently guarantee the performance of these products when applied underwater. We recommend, if possible, that you do the fixing dry and wait for it to cure before covering it with water. Beyond functionality or suitability, it is important to understand that the most critical aspect will be to choose a coating or material that will resist corrosion when installed underwater.