Installations exposed to high temperatures or that are at risk of fire, and thus of being exposed to high temperatures, require certifications that guarantee performance above and beyond a standard product.

There are certifications that use individualised studies to ensure that certified products meet parameters that allow them to withstand exposure to high temperatures for longer times.

What are the benefits of having a fire certificate?

An anchor that has been fire-tested has mechanical resistance features for a certain amount of time under fire conditions. The features are established for a particular time, in minutes, reflected as R30, R60, R90 or R120 resistances for 30, 60, 90 or 120 minutes, respectively.

How are anchors affected? Which applications require products with Fire resistance?

Fire-tested anchors should be used in cases where the fixing element must have a mechanical resistance and stability for a particular period of time in the event of a fire.

Process for obtaining the fire resistance certificate

The calculation process under fire conditions is done in accordance with Eurocode 2, part 4 (EN 1992-4), using the parameters established in the ETA.

Which tests are done during the fire resistance certification process?

The parameters for calculating the fire resistance of an anchor can be obtained empirically through Eurocode 2, part 4, or by doing experimental tests defined by the corresponding EAD under a standard temperature / time curve. This curve goes above 1,000 oC.

How is fire resistance calculated?

The fire resistance calculation of a fixing under fire conditions is done based on Eurocode 2, part 4, taking into account the fixing’s intended exposure time.

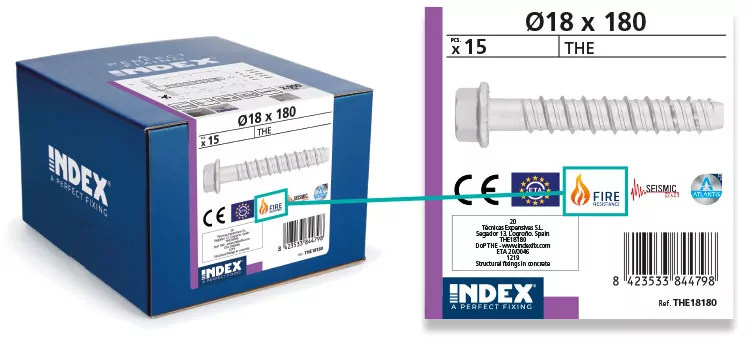

How to identify a product with the fire resistant certification?

For INDEX® products, it is indicated on the packaging of each product with fire resistance certification as follows.